William P. Cresson's Foundry, Willow above Thirteenth Street, Philadelphia, August 1847 -- zoomable image.

William Penn Cresson (b. 1814, retired from active business 1857), a member of a distinguished local Quaker family, was a hardware merchant before he decided to invest in a new foundry to manufacture within the city the goods that he traded. This was built on about half a block in the Spring Garden manufacturing district of the city, bounded by Broad, Hamilton, Thirteenth, and Willow [later James, now Noble] Streets, with good railroad service rather than waterfront access. The online version enables one to see men charging the cupola furnaces from the outside; piles of pig iron outside the boiler and steam engine house, with its tall chimney; a molding flask leaning against the wall; a molder pounding sand just inside the door; the modern, well-lit wide-span molding floor; and the horse tram bringing in fuel from the railroad running down the street nearby. There seems to be one big difference from Warnick & Leibrandt's and Abbott & Lawrence's foundries (see below): the apparent lack of multi-storey warehouse space on site.

Thanks to an 1849 broadside, we can see, perhaps, part of the explanation: Cresson may have produced more hollow ware and fewer stoves than they did, or planned to. Or perhaps, as a merchant, he already had warehouse space elsewhere?

|

| Zoomable original at Historical Society of Pennsylvania. |

I am not entirely sure why a hollow ware foundry required less warehouse space than a stove foundry, but perhaps it had to do with a steadier, less seasonal pattern of demand, so that products could be shipped through the year? The city's other major hollow ware foundry suggests as much.

Savery & Co. Iron Hollow Ware Foundry, August 1847 -- zoomable image.

The Philadelphia branch of the Savery family businesses was established in 1838, and winning prizes for its hollow ware, by 1840. Its foundry, on South Front Street between Reed and Dickinson in what was then an urban-edge neighborhood of South Philadephia, was in business by the end of that year. It looks smaller than, but otherwise not dissimilar to, Cresson's. Ware is stacked in the front yard, and going to market (or to the waterfront) by horse and cart.

* * *

To revert to Cresson, there is little apart from that broadside to describe his business and its products, except for an impressive spate of Design Patents that he took out as he established it in the stove market [see the Warnick & Leibrandt post for their similar efforts]:

- in 1846 D48, for a Summer Furnace; D75, jointly with David Stuart and Jacob Beesley, for an elegant heating stove; D88, for a cooking stove, with the same partners plus Samuel H. Sailor; and D100, for a (probably cooking) stove plate, with Stuart and Sailor;

|

| The Summer Furnace -- for outdoor cooking, or to use instead of a regular cooking stove. There is no stove pipe because, if used indoors, it would be placed on the hearth of an existing fireplace. |

- in 1847 D108, with Stuart and Beesley, more cooking stove plates; D116, the same, for a very patriotic design emblazoned with the American eagle and the slogans "Ne Plus Ultra" and "E Pluribus Unum"; and D117, with Stuart, Beesley, and Sailor, for a coal heating stove;

- in 1848 D163, with all the same partners, for a cooking stove, and D171, with Stuart and Beesley, for another elegant heating stove;

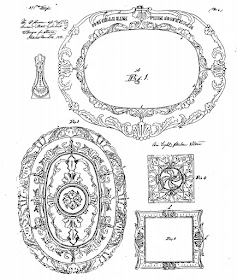

- finally in 1850 D261, for an even more attractive oval heating stove, the "Cottage Parlour Air Tight," with Stuart and a new partner, Peter Seibert, and D262, the "Radiator Screen" heating stove, with the same partners, and both "beautifully carved"; D270, the "Cast Iron Parlor Air Tight" with "very pretty" decorations, and D271, similar.

|

| D261 -- from top left, the mid-section ring, on which the oval wrought-iron body would be fixed; door and other smaller plates, including a leg; the top plate; and the bottom or hearth plate. See here for Leibrandt & McDowell's similar products. |

|

| D262. Many heating stove designs only include the more important cast plates -- in this case (clockwise from top left) top, mid-section, and hearth plate -- because the rest was fabricated by local smiths from wrought-iron plate. This seems to have been a square column for the firebox and main air chamber, flanked by two cylindrical pipes to radiate extra heat, as can be seen in some of the stoves in the Rease engravings. [See this Leibrandt & McDowell example, and compare Charles Gilbert's much more elaborate take on the same layout, above.] |

|

| D270. for an all-cast "air tight" stove, showing (clockwise from top left) a side, a leg, the top, the bottom or hearth plate, and the front (or, with a stove pipe collar in place of the air register, back) plate. |

|

| D271 -- from top left, a leg, the bottom or hearth plate, the air register plate, the feed door, and the top plate. |

|

| D261 -- from top left, the mid-section ring, on which the oval wrought-iron body would be fixed; door and other smaller plates, including a leg; the top plate; and the bottom or hearth plate. |

These patents show us more than just Cresson's and his partners' artistic ability and their, and presumably their customers', tastes. They also, like Warnick & Leibrandt's and Abbott & Lawrence's, cast light on their business connections. Who were Cresson's partners in design? Jacob Beesley was already in business as a pattern maker in 1846. The only Samuel Sailor in the city was described as a laborer, and David Stuart did not show up at all, unless perhaps as D.J., a clerk. It was 1851, by which time Sailor began a long and successful career of design patenting as sole or first-named patentee, before he first appeared unambiguously in his own name, as a carver. Beesley's independent patenting career began the following year, with the firm soon to be renamed Cresson, Stuart & Peterson among his clients. Cresson had clearly launched two of his younger associates into the artisan enterprises they would follow after he laid down his drawing pen, and the other, Stuart, he took into partnership to enable him to withdraw from active business with his "competence" achieved by 1857, allowing him to devote the rest of his life to philanthropy and community service. The other names on patents are those of their witnesses. Cresson's most frequent witness -- on four patents in 1847-1848 -- was Richard Peterson, eventually his other new partner.

There are two later accounts of Stuart & Peterson's business as it stood before and after the Civil War, in both editions (1857, published 1859, and 1867) of Edwin Freedley's invaluable Philadelphia and Its Manufactures.

* * *

Three of the Foundries in Philadelphia are occupied almost exclusively in casting Hollow-ware and Hardware Goods, which are subsequently enameled or tinned. The establishment of one of these, that of Messrs. STUART & PETERSON, is probably more extensive than any other of the kind in the Union. In this manufacture great care is necessary in the selection and commixing of the different brands of Iron, in order to obtain castings of proper tenacity ; and after such are obtained, the inside surface of the ware must be made smooth and bright to protect the enamel. In England this is effected by turning the article in an ordinary foot-lathe, the tool being guided by hand ; but the inhalation of particles of Iron proved most destructive to the lives of the operatives. The firm above alluded to, employ for this purpose self-acting tools or lathes, the invention of their master-machinist; and so admirably do they conform to the irregularities of the surface to be turned, that they seem to be endowed with almost human intelligence.

The products of this establishment embrace a great variety of

Culinary and Household articles -- Pots, Kettles, Stew-Pans, and other articles, from the smallest to the largest, as Caldrons, &c.

They deserved "very great credit for their successful efforts in competing with foreign manufactures."

Ten years later, Freedley repeated and extended his laudatory description of the company and its products:

Ten years later, Freedley repeated and extended his laudatory description of the company and its products:

The firm that have attained pre-eminent distinction in the manufacture of Tinned and Enamelled Hollow-ware is that of Stuart, Peterson & Co., on Noble street above Thirteenth. The foundry of this firm occupies an area of sixty thousand square feet, requiring to cover it an acre and a half of Slate Roofing. The moulding floor is in the form of a square, having a superficial area of twenty-two thousand five hundred square feet. Almost three hundred workmen are furnished employment constantly, and four thousand tons of American Iron are consumed annually.

This firm, by the adaptation of ingenious machinery, have so completely surpassed all foreign competitors in the production of Tinned and Enamelled Iron ware, that articles of their manufacture have a preference in all markets in the world. A detailed account of some of the processes and machines that are peculiar to this establishment will be found in Bishop's History of American Manufactures, to which the curious reader is referred. [p. 401]

[They also] produce about five hundred Stoves a week, or twenty-seven thousand in a year. They make all kinds and styles of Stoves that are in demand, and employ six persons whose business is exclusively to originate and prepare new patterns and designs of Stoves and Heating Apparatus. [p. 458].

|

| Stuart & Peterson's in 1862, five years after Cresson's withdrawal. The foundry -- the largest building in the 1846 engraving -- is the big shed with distinctive roof ventilators on the right of this view of the property. The 1846 viewpoint was not of the Willow street frontage but from the open space then behind it, now enclosed and filled in. |

* * *

-----------------------------------------------------------------------------------------

Sources:

- McElroy's Philadelphia City Directory, 1840 through 1867.

- US Patent & Trademarks Office online patent records.

- Edwin T. Freedley, Philadelphia and Its Manufactures: A Handbook Exhibiting the Development, Variety, and Statistics of the Manufacturing Industry of Philadelphia in 1857 (Philadelphia: Edward Young & Co., 1859), pp. 291-2.

- Edwin T. Freedley, Philadelphia and Its Manufactures: A Handbook of the Great Manufactories and Representative Mercantile Houses of Philadelphia, in 1867 (Philadelphia: Edward Young & Co., 1867), pp. 457-9.

- John W. Jordan, Colonial Families of America (New York: Lewis Publishing Co., 1911), Vol. 2, p. 953.

No comments:

Post a Comment

Comments will be moderated to prevent spamming, phishing, and advertising. If you wish to do any of these things, please don't waste your time and mine.