This began as an attempt to contextualize Thomas Woolson's stove-inventing and making. Thanks to having the 1839 list of customer endorsements used for the Google map, I could produce an impression of the market he was selling to. The advertisements for his stoves also made clear what he was selling against -- at first, mostly stoves made in the iron furnaces of Vermont (particularly by the Conants of Brandon and Henry Stanley of Poultney), but as the 1830s wore on an increasing flow of more modern devices from the new stove foundries of the Hudson River Valley. The out-of-state competition really provided the most important part of the context in which Woolson worked, but I thought it might also be useful to see how other New Hampshire artisans and entrepreneurs responded to the same stimuli -- increasing familiarity with stoves, even in the back country of a largely landlocked state, a growing local market, and the desire to profit by designing and making cooking and heating devices to suit it.

Blogger doesn't seem to be much good at formatting tables, so I will set out information about patentees and surviving patents as plain text instead. In each entry, the order of information is: Patentees, Residence, Patent Title, Patent Number, Year, USPTO Class, and Type. For fourteen of these patents there is nothing else in the patent record, as they were burnt in the Great Fire of 1836 and not restored afterwards. But because there were so few early New Hampshire stove patents, the survival rate is actually quite good -- a half of all those taken out.

* * *

Parkhurst, jr, John. Cheshire. Stove-pipe. X1212. 1810. Burnt.

Woolson, Thomas. Amherst. Stove for heating water & to wash & boil clothes. X1772. 1812. Burnt. See previous Woolson post.

Morey, Samuel. Orford. Leading flame in stoves by wire-gauze. X3061. 1819. Burnt.

Samuel Morey was New Hampshire's leading man of science in the early-national period. But unfortunately this is not one of his surviving or recently rediscovered patents. It might be possible to find out more from his publications in the American Journal of Science about his combustion experiments, but I haven't checked that yet. Morey sold the rights to use his "patent fire-places and chimneys" in 1814, referring to his patent 1867X (1813), also lost, which he took out in Philadelphia.

Skinner, Elijah. Sandwich. Mantel & fender for fire-places. X3501. 1822. 126/550.

The text for this patent does not survive, but it seems to be an adaptation of the normal, wood-burning parlor fireplace in pursuit of the common goals since Franklin and Rumford, greater efficiency and less smoke in the room. The fireplace is partly brick, partly metal, projecting into the room -- a sort of semi-Franklin or, as they were termed, fire frame. Improved fireplaces were a part of the same search for better methods of home heating that led to the stove, a halfway-house along the way. Improving the familiar old technology instead of embracing more disruptive change is quite a normal initial response to the challenge of the new.

This patent is our first encounter with Elijah Skinner, New Hampshire's most prolific inventor of improved heating and cooking appliances, a man who attracted plenty of attention within his small community both in his lifetime and afterwards. Here is the local history's very full account of the man and his work: his father,

Jedediah Skinner, came from Connecticut to North Sandwich about 1800. He was a noted singer and taught many singing-schools. He was a soldier in the War of 1812. His sons Elijah and Clark engaged in trade in separate stores at Skinner Corners. ... Elijah Skinner at an early day removed his stock of goods to the Centre, and for many years was a zealous and useful citizen. He was born in Lyme, Conn., September 30, 1786, and died January 22, 1871. He was above medium height, quick and lively, with fiery red hair that stood out straight from his head. He was of unbounded hospitality, and responded to every call on him for aid. He may be styled the father of Methodism here, as his house was the free hotel of that denomination; in 1824 he gave up merchandising to build the church which he had persuaded General Hoit to join him in erecting. This was completed in 1825. Elijah and his father were the first two members of the society established here. Elijah Skinner was a prominent Freemason; he never aspired to public office; represented Sandwich in the legislature of 1844 and 1845, and universally bore the reputation of being an honest man. He possessed an active and mechanical mind with great inventive powers, and in many ways was fifty years ahead of his times.

[p. 728] He foresaw the rapid strides of invention, and talked of railroads, locomotives, sending news along wires by electricity and conversing in the same manner, years before these improvements were developed, and people fancied him almost insane. From 1825 he took contracts to erect buildings and gave much time to invention. He secured fourteen patents on important scientific principles [I can only find thirteen -- HJH]. He invented a serpentine water-wheel about 1810, but found that practically the same thing had been patented in France. He was greatly disappointed, but shut himself up in a room and soon developed what he termed an endless screw [4876X, 1827], one of which he placed in a mill which he erected at the outlet of Lake Winnipiseogee [now Winnipesaukee]. Among his specifications in his application for a patent was one claiming that this wheel might be used to propel boats; and it is probable that this was the first discovery and application of the screw propeller as a motive-power. He also invented a lock to simultaneously lock and unlock a series of locks [5916X, 1830]. This principle is now universally used in locking cells in prisons, etc. He first introduced stoves into Sandwich and claimed to be the inventor of the elevated oven [HJH -- yet another one!]. In 1836 he patented an improvement in fireplaces [9502X], and many of his last years were devoted to the improvements of flues to prevent smoky chimneys and to the manufacture and improvement of stoves, and many of his make were sold through Belknap and Carroll counties as the Hoit and Sherman stove. In 1845 he purchased the tin-shop of John Fellows, placed his son Daniel in charge of it, and shortly after built a shop ... where Daniel conducted business for some time and also learned the shoe business of a man in his employ. Elijah then purchased the meeting-house he built in 1825, finished it as a dwelling and a tin-shop. Here in 1856 Daniel began the manufacture of shoes, which in a short time was transferred to a new shop on the same lot. Elijah Skinner was of too generous a nature to acquire wealth, and Daniel faithfully discharged the duties of a good son to his parents, caring for them in their last days. ... Daniel M. Skinner inherited inventive powers of a high order, and aided his father in his inventions and in making patterns. Like many New England boys, Daniel was better educated in the school of labor than in that of books.[Skinner's other non-stove patents, with links where the drawings and/or text survive, were: 2895X, Domestic Spinning, 1818; 3050X, Machine for Grinding Paint, 1818; 5501X, Commode Knob, 1829; and, with John Webster, 6734X, Vertical Lathe Mill, 1834 and 7597X, Composition Paint Stone, 1835.]

Fisher, Abraham. Claremont. Stove, Cooking. X5106. 1828. Burnt. See Woolson.

Badger, Leonidas Virgil. Dover. Making cooking furnaces & ovens, called the improved portable furnace & oven. X5355. 1829. 126/274.

The text does not survive, but the illustration shows what seems to be an adaptation of an established New England style of heating stove, its body made of sheet iron and only its base and legs made of cast iron -- of the kind that Isaac Orr would go on to patent. These stoves were usually fed chunks of wood through the lid on the top. Badger seems to have adapted his to burn coal as well or instead (there is a grate), and to have abandoned the usual effort to make it air-tight for efficient, slow burning. This is because he has paired it with a modified sheet-iron or tin "tin kitchen" or reflector oven to sit over the large hearth plate, which needed the heat of a burning, glowing fire in order to work. Tin kitchens (see below) were common utensils for open-hearth cookery, placed near the fire and cooking by radiant heat, which their shiny surfaces reflected onto the food to be cooked. Badger's seems to have two shelves and (probably) a lifting or even sliding curved access door.

Badger was born in Portsmouth, NH, in 1806. Dover was a seaboard community of the kind where stoves, imported from the Philadelphia region, first became common in the state. Its meeting house had acquired its first stove some time after 1822 -- if standard New England practice applied, it would probably have been the first public building, and one of the first buildings altogether, adopting stove heating. In January 1828, he was among the more progressive citizens of Dover -- particularly its growing manufacturing interest -- who seceded from the Congregationalist parish and established a Unitarian church. Badger seems to have moved back to Portmouth, where he patented a ship's windlass [8264X] in 1834 and fuel-saving devices for foundry cupolas and forge hearths in 1835 [9269X and 9275X], before moving to New York, where he became a stove dealer, between 1839-1842; and then to the midwest, ending his career as a wealthy Chicago banker. His 1830 portrait is in the Chicago Historical Society, while the doll house (a model of his place of birth) that he built in 1858 resides in the National Society of Colonial Dames' Clark House museum.

Richards, Josiah. Claremont. Double-furnace cooking Stove. X5601. 1829. Burnt. See Woolson.

Hubbard, Oliver. Claremont. Manufacturing stove-funnels, tin or copper ware. X5712. 1829. Burnt. See Woolson.

Moore, John. Ackworth. Stove, Cooking. X5951. 1830. 126/1R.

This, rather than Woolson's the following year, seems to be the first "proper" cooking stove invented in New Hampshire whose patent survives. The description is very detailed. This was evidently a real design, probably made to order (no specific dimensions are given; it would be sized to suit the buyer) and, like Badger's and Woolson's, composed partly of cast and partly of sheet (wrought) iron. Also like Woolson's, its side plates were curved rather than square, possibly for ease of working the sheet iron. Like Woolson's later models, Moore's stove had one large boiler hole (in his case right over the fire, at the front of the stove) and two smaller ones. Again like Woolson's, the oven was of sheet iron, surrounded by flues on all sides, and damper-controlled.

John Moore (1795-1834) was "a mechanic and farmer. In the winter he engaged in the manufacture of spinning wheels and reels and in the summer engaged in farm work." Moore travelled all the way to Washington, DC, to get his patent registered. But it does not seem to have left much of a trace in the market or the historical record. He may not have had the capital to exploit his invention; he certainly did not have much time. However, his heirs (or assignees?) must have seen or hoped for enough value in his ideas for it to be worth the effort of restoring the patent after the Fire.

[According to the history of Loudon Township, cooking stoves were introduced several years later than heating stoves -- the meeting house acquired its first in 1820. "There was at first a strong feeling against the use of them, and it required much effort and persuasion to induce a person to buy one. The kind first in use was called the 'Moore Cooking-Stove.' After several years the prejudice existing against their use subsided, and they gradually came into use." Loudon is about 60 miles east of Acworth.]

Skinner, Elijah. Sandwich. Gridiron / Baking Iron. X6164. 1830. 99/447.

As we saw with Skinner's 1822 fireplace patent, he was still devising improvements for traditional fireplaces rather than adopting the new technology of the closed stove. This is interesting because it says something about the requirements of the community of back-country consumers that he served. His "Baking Iron" was a piece of sheet metal 18-30" long and 6-10" high, designed to ease the tasks of "baking, toasting, or broiling with one and the same instrument." It would take the place of a "cake block, toast iron, gridiron and broiler" -- some of the other soon-to-be-forgotten kitchen implements of the open-hearth era.

Bacon, Reuben & Marshall, W.E.. Walpole. Double oven in chimneys. X6369. 1831. Burnt.

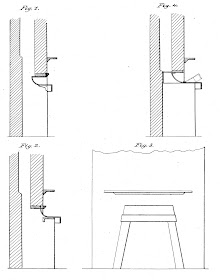

Skinner, Elijah. Sandwich. Mantel for fire-place. X6644. 1831. 126/550.

His "inverted arch or curved mantel fireplace" was essentially an update on his 1822 patent. The metal mantel was made of cast or sheet iron, or burnished sheet brass. The purpose was "better securing the draught of smoke and conducting & radiating

the heat into the room."

Woolson, Thomas. Claremont. Stove, Cooking. X6655. 1831. 126/1R. -- See Woolson.

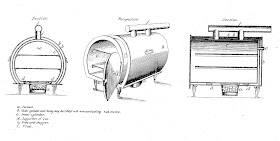

Goddard, William. Portsmouth. Portable oven. X6795. 1831. 126/273R.

Goddard's patent provided detailed instructions for constructing this new oven from sheet iron or tin, with cast or wrought iron fittings, including the base. It consisted of three concentric spaces -- the oven itself; a space around it where the combustion products of the furnace circulated en route to the flue; and an outer insulated shell. What he does not say is how or for what purposes he envisaged that his oven would be used -- but other sheet-iron ovens like this being invented at the same time were designed for large-scale bakers serving urban and maritime consumers. Goddard was a Portsmouth merchant and capitalist whose wealth was almost wiped out by the Crash of 1837. There is no evidence that this oven ever was built for sale and used.

Knight, J. Stoddard. Fire-place & oven. X6864. 1831. Burnt.

Foot, Henry A. Dover. Stove, Cooking. X7321. 1832. Burnt.

Ingalls, Joseph. Sandbornton. Sheet-iron fire-place. X7592. 1833. Burnt.

Skinner, Elijah. Sandwich. Draught in chimneys. X8134. 1834. Burnt.

Childs, James. Henniker. Stove, Cooking. X8531. 1834. 126/1R.

James Child (b. 1795) was "an ingenious and skillful mechanic, the inventor and patentee of one of the first if not the first [no, not the first -- HJH] cooking-stoves ever manufactured in the State of New Hampshire. ... His only surviving son writes: 'Among my earliest recollections is learning to read my father's name upon our kitchen stove.'"

Child's was a proper cooking stove, like Moore's and Woolson's in its construction from wrought as well as cast iron, and its partially rounded form. It followed Moore's in having a large front boiler, and anticipated the mature form of Woolson's by having boiler holes made of concentric rings of cast iron, and therefore adaptable to cooking utensils of different sizes.

His patent provided detailed dimensions as well as instructions on constructing his stove. The hearth A was 25" wide, the firebox B 19", and the sheet-iron oven C 22" wide and 17" long but only 8" high, with flues above and below. The stove bottom was a casting 1" thick, i.e. this was a large, substantial appliance, but, like Woolson's, quite low-down -- the level cast-iron stove top was just a foot above its bottom, with the legs adding a few inches more -- to suit users accustomed to open-hearth cooking.

His stove's claimed advantages were partly its size and convenience -- five boiler holes, one of them very large, all but the two smallest adjustable in size; a larger oven than in any stove of equal size; flues so organized and damper-controlled as to heat the oven or the cooking top exceptionally well. Child's stove must have been heavy as well as quite costly, suited to a large household or small hotel, built to order or in small numbers, and not designed for large-batch production and interregional trade like those beginning to pour out of the Hudson Valley's furnaces.

Bean, Ira A. & Skinner, Elijah. Sandwich. Fire-place. X8870. 1835. 126/506.

This is another of Skinner's transitional devices -- an attractive neoclassical parlor fireplace with a cast-iron insert designed to make it suitable for doing a certain amount of cooking. The description is very detailed -- measurements, methods of construction and use. Bean and Skinner's objects with this design were "to save room and fuel, furnish a cheap and convenient apparatus for cooking, and at the same avoid the impure air occasioned by close stoves, and the steam from cooking stoves." Though Skinner had not yet designed a stove, he was evidently very familiar with them, and with new and unaccustomed users' objections to them. Skinner's witnesses on his patents were usually identifiable as members of the local elite -- lawyers, educators, merchants, selectmen -- and it's reasonable to think that they were the customers, too, for his attractive modern fireplaces, and their objections to stoves and stove cooking were ones he shared. Ira Bean (b. 1798-99) was a local lawyer.

Skinner, Elijah. Sandwich. Stove, Cooking. X8889. 1835. 126/8.

By 1835, however, Skinner had evidently determined to join the growing competition to produce cooking stoves, as well as providing improved and modified fireplaces for those who were reluctant to adopt them. This cooking range, too, was a product for wealthier customers and larger households. It was made to fit into a common cooking fireplace, and replace it permanently and completely. It was constructed of cast-iron plates, with a large sheet-iron elevated oven C, and three boilers, one large and two small.

The curious vertical columns at the front corners, and the sheet-iron tubes at the rear venting into the main flue, were designed to address the consumer objections to stove cooking that Skinner referred to in the previous patent -- the unaccustomed cooking smells that pervaded the houses of people who did not, like ordinary folks, live in their own kitchens, when the old large-mouthed cooking hearth was closed up and a stove took its place. To deal with this problem, Skinner was incorporating a ventilation system (probably not very effective) into his range.

Cochran, Rodney G. Francistown. Stove, Cooking. X9344. 1836. 126/1R.

Similar to James Child's stove -- a bottom of cast iron, optionally partly of thick sheet iron too; the body 40" long by 22" wide, with the projecting hearth 25" wide and the new feature (new, at least, in New Hampshire stoves, but present in the Hudson Valley for at least a decade), a "sunk hearth" (Fig. 1, A) for ash removal etc., also present in Woolson's stove by 1839. The body of the stove was 14" high, the plates again partly cast and partly sheet iron, depending on the amount of heat they had to take. The oven (the right-hand doors in Fig. 2) was 8 x 11.5" and the full width of the stove; the smaller door to its left was for adding fuel to the fire, a useful feature becoming common on cooking stoves whose front hearth might be occupied by a reflector oven, or whose sunk hearth might be in use for grilling. There were four boiler holes, one very large at the front, and all but the smallest adaptable, via concentric-ring construction, to take pots of different sizes. Because Cochran's stove was so similar in appearance, construction, and function to others long on the market, the only way he could claim that it was significantly different enough to warrant a patent claim was by pointing to its internal flue and damper arrangements, which was becoming the stove inventor's usual recourse by the 1830s. Cochran (b. 1802) was a store-keeper and temperance advocate.

The Francestown local history has plenty to say about stoves, casting a light on the development of a market for them in New Hampshire:

(a) Stoves in Churches:

[A]nother cause of disturbance appeared in the fall of 1821. A subscription-paper had been started to buy a stove for the meeting house, and the danger from extravagance on the one hand, and from fire on the other, seemed so great as to stir the whole town with excitement! An article had been in the warrant as long before as Mar. 1815 "to Purchase stoves for the Meeting-House," -- which had been promptly and vigorously dismissed. But as there was no hope that the town could be induced to vote such a costly and perilous innovation a few of the more progressive spirits of that day raised among themselves, $86.62, by subscription, went to Claremont, N.H. and bought a stove, and, without authority from the town, did deliberately set it up in the meeting house, and did kindle a fire in it! At once there was a cry of alarm. Some sensitive souls thought the dignity of the town had been insulted by this usurpation of rights! Some could not sleep for fear of being burned up! Something must be done! The conservatives determined to make a stand, and "petitioned for a town-meeting; and, after some delay, (which the "stove-party"' apparently favored,) a legal meeting was called for Jan. 12, 1822. But meanwhile the dreadful Stove worked well, and the fingers were warmed, and the large, cold church was made much more comfortable, and no buildings were burned; and consequently every sabbath made votes for the "Stove-party!" One or two fearfully cold sabbaths settled the matter! And by time of the town meeting the Stove conquered, -- and they voted that the

"Stove Lately pt up in the Meeting House remain for the Present!" They also

"Voted that No Fire be taken from said Stove by any persons having Stoves for their use," i. e. they would not let them fill up their foot-stoves from it. And at the following March meeting, they chose [p. 176]

"David Lewis, Levi Bixby and Daniel Lewis a committee to take Charge of the Stove in the Meeting House."

They counted it a very important matter and put some of their first men on the committee! Francestown was several years ahead of most other towns in this vicinity in warming the church. That first stove and pipe, delivered, cost $117.68. But it puzzles us at this day to know how previously they could live without it, in a house as cold as a New Hampshire winter could make it, men, women and children, all day long! Surely they were willing to ''suffer hardship" for the sake of their religion!This is a very normal "first stove in the meeting house" story, but what interests me about it is (i) the high cost -- $81,500 in 2014 values, using the nominal GDP per capita means of comparison, (ii) the fact that men travelled to Claremont, 47 miles north, to get their stove -- which suggests that Elmer and Woolson or somebody else may already have been making stoves there, and (iii) the comment on how slow rural New Hampshire was to take the first step in the "stove revolution," heating the meeting.

(b) Stoves at Home:

After a discussion of the massive wood-consuming open fires, supplemented with the brick bake oven once pioneer log cabins were replaced by houses with proper chimneys, we get to the Age of Progress:

After a time the "tin baker" was invented, it being a sort of hand oven to set up before the fire. It was placed on legs about six inches above the hearth, was closed behind, and opened like a tunnel toward the heat, was light, was made of tin and kept scoured and shining, and it did some excellent cooking. It was a quick way to cook, answering a fine purpose in any sudden call. It was generally introduced in this section about 1840, though known and used before. I remember the first one brought to my father's house, how it astonished us, and how great an invention it was declared to be. But it was soon superseded by the cooking stove. Stoves had long been in use more or less for heating purposes. As early as 1815 an article was in our town warrant to "purchase stoves for the meeting-house." It was, however, many years before they were used for cooking. The first cooking-stove the writer ever saw appeared about 1843, being a rude affair as compared with the elegant ranges of the present day. There was great prejudice against them, and even fear of them, and they gained very slowly their way to popular favor, not being in general use in this vicinity much before 1850. At first they were set up beside the old fire-place, and both were kept running at the same time, wood being so plenty that they cared not how much they burned.

Skinner, Elijah. Sandwich. Fire-place. X9502. 1836. Burnt.

Pearson, Benjamin H. Warner. Stove, Cooking. X9569. 1836. 126/1R.

A very peculiar design, though essentially quite conventional -- another box stove with a most unusual shape, and the usual configuration of boiler holes for the rural New Hampshire market. Pearson's description of his "Open Frame Cooking Stove" includes plenty of measurements, and specification of which parts were to be of cast and which of sheet iron, but no other information about construction, nor any account of why his stove had such a strange appearance. The best explanation is that the front was an iron open fireplace, basically a Franklin without any doors, hence its flaring shape, with the stove body tacked on (see similar "oven Franklin" designs in Maine at the same time).

Pearson made the usual claims about the superior heating of his oven, his control dampers, etc., but this design does not impress as practical or marketable. It's a bit like Skinner's earlier patents -- a transitional device, aiming to keep the familiar (in this case an iron fire frame or open Franklin) while bolting on what consumers increasingly demanded, a functional cooking stove.

Currier, Ezekiel G. Warner. Stove, Cooking. X9690. 1836. 126/1R.

This "Open and Close Stove, designated as No. 1," was similar in concept to Pearson's, but rather better devised. It was basically an open-front Franklin, with the wood fire in the normal place for a cook used to working at the hearth, i.e. near the floor (presumably a hearthstone); but boiler holes were fitted in the jambs either side, and the whole fireplace could be boxed in, turning it into a kind of stove, with one large boiler on top. Currier then added an elevated oven behind the firebox, heated with flues on all sides, which would work whether the stove was in its Open or Close modes. This idea was quite popular at the time in other well-forested districts beginning the transition from open-fire to stove cooking (e.g. Maine), and was clearly designed to produce an appliance not too startlingly different from what consumers were used to, but giving them most of the benefits of the new technology at the same time.

Currier, Ezekiel G. Warner. Stove, Cooking. X9691. 1836. 126/1R.

A minor variation on the above, "designated as No. 2," but so little different that it shares the same illustration. Even a careful reading of the several pages of description fails to explain why Currier bothered to patent two almost identical stoves, incurring double fees, and on the same day, 2 June, shortly before the old patent system was replaced by the new, more rigorous 1836 law.

Andrews, E. Bradford. Stove, Cooking. X9818. 1836. Burnt. COOK

Lear, Asahel. Wendall. Stove, Cooking. X9838. 1836. Burnt. COOK

Currier, Ezekiel G. Warner. Stove, Open & close. 17. 1836. 126/1R Mislaid.

It is a pity that the Patent Office appears to have lost or mixed up the details of Currier's third stove patent, apparently one of the first taken out under the new 1836 Act and system. In the absence of the text, we are left with another version of the same question asked re 9690X and 9691X -- why go to the trouble and expense of patenting something whose name suggests it was just another minor variation on the same idea? The best explanation is that he made an additional improvement in 1838, and in the confusion caused by the Great Fire of 15 December 1836, following on from the introduction of a new system of granting and recording patents that summer, the Patent Office gave it the same date as the original (whether 9690X or 9691X) and a new-series number. In other words, there were probably only ever two almost identical Currier patents in summer 1836, but the fact that he restored both lost patents and registered a modification to one of them two years later suggests that they must have been of some value to him; or at least he continued to believe that they would be.

Smith, Nicholas. New Hampton. Stove, Combined Parlor & Cooking. 71. 1836. 126/4; 236/31.

Smith's is in many respects comparable to the other two Franklin-fronted stoves from Warner, NH (Pearson's and Currier's), but this new-series patent is much more professional than either of them. The drawing, with its oblique side view, sectional plan, and drawings of all castings, is particularly informative. Under the 1836 Act, patent applications had to be examined by Patent Office specialists before being granted; most of the surviving old-system New Hampshire patents set out above would not have survived this scrutiny.

Smith's patentable modification to what was then an established stove type, the "Oven Franklin," which he thought of as appropriate to sit in the parlor rather than the kitchen, is hard to see in the above drawings without magnifying them and reading them alongside the text. The firebox (the left-hand box, numbered 10, in the body of the stove in the lower-centre figure) could be moved to and fro depending on whether the stove was supposed to be used primarily as a parlor heater or for cooking. This was probably a design weakness -- unlubricated iron sliders, supposed to operate in an environment of extreme heat under a bed of ashes, are far from ideal -- but Smith's plan was quite common at the time. This was before stove designers had worked out that the best way to make their stove's heat controllable was probably the simplest: making it as near airtight as possible, and then managing it with the air supply and chimney damper alone. En route to this objective, designers experimented instead with different ways of moving the fire closer to, or further from, the oven and boiler holes. One final feature of Smith's stove: this patent is the first explicit mention in New Hampshire of burning coal as well as, or instead of, wood.

Kimball, William B. Peterborough. Stove, Cooking & heating. 290. 1837. 126/1R.

Kimball's was another transitional "double stove," i.e. a familiar Open Franklin attempting to double as a cooking stove. Kimball's appliance, like Smith's, could burn coal as well as wood, but he solved the problem of running it as a closed stove in a different way: as well as a traditional hearth for wood, equipped with andirons, there was a firebox and grate above it, Fig. 2, (viewed from above with top plate removed), for burning wood or coal and accessed via the small square hatch to the left of the oven door in Fig. 4. Note the large boiler hole in the front of the top plate, right over the fire -- a standard feature of these New Hampshire stoves. There seems no reason to think that Kimball's design was unduly complicated or would not have been suitable to do much of the cooking for a small household wealthy enough to have a parlor as well as a kitchen. Kimball, b. 1801 in Vermont, had come to Peterborough in 1830. He was described as "a mechanic, a superior pattern-maker, and also the author of many mechanical and patented inventions. Built his house, situated on Pine Street, iii 1836, where he now r[esides]."

Skinner, Elijah. Sandwich. Stove, Cooking. 429. 1837. 126/8; 142/20; 62/345.

This was Skinner's pièce de résistance -- a built-in, brick-set range, though he once again called it a stove. It was built “on the principle of the common diving-flue stove,” and Skinner's contribution was “to render the expense of manufacturing, less; (conveniences considered) and to produce a regular heat on the oven.” It was quite a large appliance – 3'6” long, 16-18” wide. In many respects this range illustrated that Skinner was quite up-to-date with stove design: it had the fire above the oven, the same as the most modern New York State stoves which would soon become the American standard, and the smoke circulated down and around the oven; it could burn coal as well as wood. But in others it was a backward and inconvenient design, e.g. the firebox was at the end, and there was no fuel feed door in the front plate, as in the better range designs.

Skinner's stoves were still quite expensive, customized products, assembled and fabricated to fit customer requirements and involving quite a lot of "mason work." They were permanent installations, and Skinner had not settled on a single design, as his three illustrated versions and his language of "contemplat[ing] making others of various and different forms" demonstrate. Skinner was not aiming for batch production and a large market; in eastern New Hampshire, there wasn't one.

Heywood, Simeon & Fisher, Leonard P. Claremont. Stove, Cooking. 896. 1838. 126/1AE.

This was the first New Hampshire stove that looked something like the all-cast, factory-assembled stoves becoming standard among the more advanced Vermont and New York furnaces and foundries. It had four boiler holes and an oven insulated from the direct heat of the fire by flue spaces wrapping around it. Like Hilliard's addition to the redesigned Woolson stove in 1839-41, it had a "sunk hearth" with a fifth boiler hole in it. Its firebox had a convenient side feed door.

The stove's form, with two boilers immediately above the fire, and another two, slightly higher, above the oven to the rear, was that of the popular "Premium," "step," "horseblock" or "Jew's Harp" stove, introduced in Albany and Troy at least five years earlier. It was a fully commercial product, described in the patent and sold as "Heywood & Fisher's Improved Premium Cooking-Stove." Its advantages were “its perfect symmetry; compactness, convenience, and utility, combined with the economy in fuel.” There was nothing idiosyncratic about it all. It was ready to compete in the market. Like the later models of Woolson's stove, this too was manufactured at the Tyson Furnace in Vermont, which advertised it as "a very neat pattern..., embracing all the good qualities of a small stove." [Advertisement, "Stoves, Stoves," Vermont Watchman & State Journal (Burlington), 1 Feb. 1841, p. 4. Tyson also made and sold stoves to Badger's designs.]

The stove's form, with two boilers immediately above the fire, and another two, slightly higher, above the oven to the rear, was that of the popular "Premium," "step," "horseblock" or "Jew's Harp" stove, introduced in Albany and Troy at least five years earlier. It was a fully commercial product, described in the patent and sold as "Heywood & Fisher's Improved Premium Cooking-Stove." Its advantages were “its perfect symmetry; compactness, convenience, and utility, combined with the economy in fuel.” There was nothing idiosyncratic about it all. It was ready to compete in the market. Like the later models of Woolson's stove, this too was manufactured at the Tyson Furnace in Vermont, which advertised it as "a very neat pattern..., embracing all the good qualities of a small stove." [Advertisement, "Stoves, Stoves," Vermont Watchman & State Journal (Burlington), 1 Feb. 1841, p. 4. Tyson also made and sold stoves to Badger's designs.]

Heywood (b. 1796/8?) was a shoe maker by trade, born in Acton, MA. He "went into trade for a time in Charlestown, N.H., removed to Lunenburg, Mass.,— was in mercantile pursuits and became postmaster and town treasurer — removed to Claremont, N.H., in 1835." His 1835 brick-built Greek Revival store still stands. Later in his career he “did something in the furnace department, but more at wood-work – manufacturing horse and

hand-rakes and various other articles.” Fisher (b. 1807) was a long-time Claremont resident. "When ten years old he

accompanied his parents to New York State, where he assisted his father

in business until he was twenty-two years old. He then returned to

Claremont for the purpose of helping his grandfather, and eventually he

inherited the homestead. He cultivated the farm successfully; and during

the winter season he cut and hauled timber, which he manufactured at his

own saw-mill into building material. He erected a number of houses, all

of which are now standing. He was naturally cheerful, and was highly

esteemed for his genial disposition and kind-heartedness." These brief biographies don't really explain why either of them should have been such competent stove inventors.

McCollum, Elbridge. Weare. Stove, Cooking. 1330. 1839. 126/506.

McCollum takes us back into the territory of idiosyncratic, supposedly dual-purpose stoves -- "by which the

ordinary open, or Franklin, stove is made convertible into a close

cooking-stove, and combined with ovens on each side thereof in such a

manner as to combine economy in the use of fuel, with convenience in

the application of heat, either to the purposes of cooking or of

heating apartments.”

It could actually be a sort of warm-air furnace, for heating upper rooms, too, as well as a cooking and room-heating stove -- "I sometimes add a heater for heating air, which air may then be conducted, by means of tubes, wherever it may be wanted.” That, too, was not an original idea. Convertibility, complication, and dual or triple effects, or even more, appealed to inventive Americans; less so to everyday consumers. I have found no evidence that this stove turned into a marketable product, and nothing about McCollum either.

Weare seems to have been quite slow to take up stove heating: the meeting house did not get its first until 1832, "it having become fashionable to have them," though people had been asking for one since 1824; the town house did not install one until 1845, after four years of argument and indecision. No stove trader was recorded before 1848, and no iron foundry before 1851.

It could actually be a sort of warm-air furnace, for heating upper rooms, too, as well as a cooking and room-heating stove -- "I sometimes add a heater for heating air, which air may then be conducted, by means of tubes, wherever it may be wanted.” That, too, was not an original idea. Convertibility, complication, and dual or triple effects, or even more, appealed to inventive Americans; less so to everyday consumers. I have found no evidence that this stove turned into a marketable product, and nothing about McCollum either.

Weare seems to have been quite slow to take up stove heating: the meeting house did not get its first until 1832, "it having become fashionable to have them," though people had been asking for one since 1824; the town house did not install one until 1845, after four years of argument and indecision. No stove trader was recorded before 1848, and no iron foundry before 1851.

Ferren, Ebenezer. Haverhill. Stoves, Constructing flues of cooking. 1408. 1839. 126/1AE.

Ferren's detailed drawings showed a modification of an ordinary flat-top stove -- as he acknowledged, "The general form of my

cooking stove is the same with that of many others now in use." Ferren's stove had the usual features the market expected in a new stove by then -- the sunk hearth, the large boiler hole as well as the two smaller ones, the side feed door on the firebox, the control dampers and the oven surrounded by smoke flues on all sides for (supposedly) even and efficient heating.

What he seems to have been attempting to do was to produce a simple, convenient, flat-topped stove, rather than a "premium" type, with its boiler holes on two levels, perhaps a less usable top plate, and more complicated castings; but with some of the advantages of the premium, notably that the oven did not back straight onto the firebox, which led to heat-cracking of the plate between them and very uneven heating of the oven. The Franklin Institute gave Ferrens's design a rare endorsement: his stove appeared "well arranged for governing and directing the draught."

Ferren was born in 1800 and died in1845, but the local history does not say anything about him. However, it does tell us that iron cook stoves were on sale in the town from at least 1820 onwards [p. 321], and that "As every thing from 'down below' as it was called [Haverhill was midway between Boston and Montreal, two days by stage from either big city], must be brought by the team, the people's wants were met largely by local manufactures. ... A foundry transformed the old iron brought in into stoves and other useful articles." [p. 381] This was probably the Oliverian Iron Foundry, where "all kinds of mill irons, sleigh and sled shoes, hollow ware, cauldron kettles, cook stoves and parlor stoves were manufactured." [p. 368] So Ferren would have had a developed local market to hope to supply and, until it closed, unfortunately in the year after he secured his patent, an experienced local manufacturer to work with too.

What he seems to have been attempting to do was to produce a simple, convenient, flat-topped stove, rather than a "premium" type, with its boiler holes on two levels, perhaps a less usable top plate, and more complicated castings; but with some of the advantages of the premium, notably that the oven did not back straight onto the firebox, which led to heat-cracking of the plate between them and very uneven heating of the oven. The Franklin Institute gave Ferrens's design a rare endorsement: his stove appeared "well arranged for governing and directing the draught."

Ferren was born in 1800 and died in1845, but the local history does not say anything about him. However, it does tell us that iron cook stoves were on sale in the town from at least 1820 onwards [p. 321], and that "As every thing from 'down below' as it was called [Haverhill was midway between Boston and Montreal, two days by stage from either big city], must be brought by the team, the people's wants were met largely by local manufactures. ... A foundry transformed the old iron brought in into stoves and other useful articles." [p. 381] This was probably the Oliverian Iron Foundry, where "all kinds of mill irons, sleigh and sled shoes, hollow ware, cauldron kettles, cook stoves and parlor stoves were manufactured." [p. 368] So Ferren would have had a developed local market to hope to supply and, until it closed, unfortunately in the year after he secured his patent, an experienced local manufacturer to work with too.

Cochran, Rodney G. Francistown. Stove, Cooking. 1814. 1840. 126/6.

This was not really a cooking-stove patent, despite the way the USPTO recorded and classified it (the drawings are labelled more accurately, "Heating Drum," which is what would have been warmed by air from the outflow pipe F at the back of the stove after it had passed up through the flue spaces from the intakes C below the firebox and oven, and then the heat exchanger under the top plate). This add-on contraption would make the stove function a bit like a warm-air furnace, generating a current of heat to be transported to upper rooms in a house through sheet-iron tubes. The idea was not new -- it dated back at least as far as Oliver Evans, the great Philadelphia mechanician, and figured as an illustrated example of problem-solving innovation in his Young Millwright's Guide's many editions from the 1790s through mid-century. Nor was it impracticable -- stoves and, particularly, kitchen ranges with air-warmer attachments would be sold by major manufacturers through the late nineteenth century. It was an attractive proposition to inventors and consumers in a community becoming ever more enthusiastic about minimizing the wastage of fuel and heat, and increasing domestic comfort.

Cochran's patent drawings show his heat exchanger fitted to a standard flat, square, small-oven stove, but this is not conclusive proof that the stove was one he made and/or sold, or that his invention ever made it as far as the market, or even beyond his workshop. His appliance would have interfered with the heating of the oven and cooking pots, which was the main purpose of kitchen stoves; it would also have needed to be customized to stoves with different internal arrangements. In any event, Cochran did not stay in the stove business long enough to find out, abandoning it the following year to sell subscriptions to the Boston Congregationalist magazine throughout New England and the Yankee diaspora for the next twenty years.

Hilliard, David H. Cornish. Stove, Cooking. 1858. 1840. 126/13. [see Woolson].

* * *

SO WHAT?

Interesting though the above information about some of New Hampshire's stove inventors through the "Age of Democratic Invention" may have been, what if anything does it add up to? What shapes and patterns are discernible in this information? What's its significance?

(1) The Shape of the Data

Compare these two versions of the same map -- the first, locating all New Hampshire stove inventions through thirty years; the second, superimposing the recorded locations of a sample of Thomas Woolson's stove customers, 1833-1839.

What can we see? With few exceptions, stove patentees resided in the south-west corner of the state (the modern counties of Grafton, Sullivan, Cheshire, Hillsboro, and Merrimack), which is also where Woolson found most of his in-state markets. Woolson did not sell into Belknap and Carroll counties to the east of the Merrimack and Pemigewasset rivers. Why? One would need to know more about the economic and in particular the transportation geography of pre-railroad New Hampshire than I do at the moment, but the best explanation I can think of is that Woolson's stove sales followed the lines of least resistance in an age of costly overland transport -- north and south along the Connecticut River valley, which meant that the towns of south-eastern Vermont were much more accessible to him than much of his own state; and along the highways and turnpikes leading from the valley south-east towards Boston. Skinner, meanwhile, supplied the even less sophisticated needs of the relatively isolated consumers of Belknap and Carroll counties.

New Hampshire stove patenting took place within these two clearly demarcated territories, among the local merchants, artisans, and manufacturers of these largely agricultural counties' small commercial centers. Where it did not happen much is in the state's major towns and emerging industrial cities along the southern part of the Merrimack Valley, from Concord to Nashua, or in the entire south-east of the state (modern Strafford and Rockingham counties).

This is initially surprising: the south-east corner is where New Hampshire was beginning to urbanize and industrialize, a bit, and where one would expect the market for stoves to have been growing fastest, and with it the stimulus to invention. This is certainly what one sees in other states at the time, including New Hampshire's big neighbour to the south: in Massachusetts in the 1830s and 1840s, for example, the best predictor of the number of tin shops per head of population in a county -- a good proxy for the existence of a market in stoves, as tinners sold, installed, and serviced them -- is its rate of population growth, which is in turn a proxy for industrialization. Rapid population growth means lots of new household creation, construction, and outfitting.

New Hampshire's demographic history in these years was, however, quite distinctive. An overwhelmingly rural state, its greatest export was people. At a time when the United States enjoyed population growth rates comfortably exceeding 30 percent in every decade from the 1790s to the 1830s, New Hampshire's rates by the 1820s and 1830s were 10.3 and 5.7 percent, respectively -- falling from less than a third to less than a fifth of the national average. Within New Hampshire, there was some urbanization -- its six largest towns' combined population increased in the 1820s and 1830s at the respectable rate of 36 percent per decade, with impressive rates in Dover in the 1820s (81 percent), Nashua in the 1820s and 1830s (111 and 151 percent), and Manchester in the 1830s (269 percent) because of the growth of manufacturing.

In the counties where stove patenting activity and small-scale manufacture were concentrated, however, the picture was very different: Strafford (which then included Belknap and Carroll), Skinner's market, only recorded 3.8 percent population growth in the 1830s, despite containing Dover, the county seat, i.e. the hinterland was probably depopulating; Sullivan, where the Woolsons were based, managed 3.4 percent. The rest of their sales territory -- Cheshire, Grafton, Hillsborough, and Merrimack counties -- returned a mixed picture: -2.2 and 4.7 percent in Merrimack and Cheshire, 9.4 percent in Grafton to the north and 12.6 percent in Hillsborough, which contained both Manchester and Nashua, to the south. Skinner and the Woolsons were therefore probably generally selling to customers updating or replacing existing household equipment, rather than to new households, of which there were few. This makes particularly good sense of Skinner's and others' patterns of invention, with its focus on improving the fireplace, first of all, and then of producing hybrid devices combining the familiar and the new -- open Franklins with a cook stove bolted on the back.

So there is an obvious explanation for the apparent paradox, that stove patenting and small-scale manufacturing and marketing seems to have been a hinterland activity, taking place in near-stagnant communities haemorrhaging people at the same time as they experienced modest economic growth and diversification:

- The state's more dynamic towns in the south-east of the state, which hardly figure in the patenting map or among Woolson's customers, were indeed the New Hampshire vanguard of the processes of converting from the open fire to the closed stove, and also from wood fuel to a mixture of wood and coal (which, along the north-eastern seaboard in the 1830s, mostly meant Pennsylvania anthracite), as one would expect. But they got their stoves the same way they got their new source of fuel: by sea, at first from the Philadelphia region, and later from the Hudson Valley suppliers trading through New York to wholesalers in Boston, Salem, Newburyport, and Portsmouth; and by river, canal, or even early railroad, as well as by turnpike, for local distribution inland. There was little opportunity, and no space, in their markets for small, inexperienced local suppliers, and little incentive for inventive and ambitious local men to apply their energies to stove patenting and manufacture.

- In up-country New Hampshire, on the other hand, small-scale local stove makers had the market more or less to themselves, until transportation improvements opened them up to outside competition. This was the environment in which Woolson, Skinner and a few others achieved their modest and short-lived successes; and the growth of a stove market in the hinterland is what provided the stimulus for local artisans, merchants, and others to seek their fortune too in attempting to satisfy its needs.

This hypothesis is admittedly speculative, but it seems to make the best sense of the spatial distribution of stove inventors, on the one hand, and of the customers of the most successful of these back-country proto-industrial stove makers, Thomas Woolson, on the other.

It can be given some extra credibility by two simple procedures: (a) comparing stove invention with other recorded patenting activity in the state in the 1820s and 1830s; and (b) seeing what happened to stove invention after 1840, by which time the invasion of the upcountry market by cheaper and more modern out-of-state products was well under way.

(a) In the last decade of the old patent system (I don't have post-1836 non-stove patents in such a convenient form for quick examination) there were 24 stove patents taken out by New Hampshire residents, and 138 others. I have not (yet!) done as careful a mapping of the latter as I did with stoves, but a simple count is quite revealing by itself: 16 around Nashua (10 in Dunstable, 6 in Hollis); 12 in Portsmouth; 8 in Keene. There were also clusters in smaller, inland communities -- 10 in Sandwich (largely because of Skinner's enthusiastic patenting of other mechanical devices); 8 and 7 in the Connecticut River valley towns of Bath in the north, and Walpole in the south. There was then an apparently (until analyzed in detail) random scattering of inventions in other parts of the state. But, even without thorough scrutiny, it is evident that the pattern of distribution reflects better the American norm at that time, with larger industrializing towns, and those on the main channels of trade, contributing a share of inventive activity disproportionate to their share of population.

(b) The answer to the question "what happened to stove invention in New Hampshire after 1840?" is much easier to answer. It almost immediately ceased -- just one more patent, in 1842 (Andrew Walker, Jr, "mechanic, of Unity, New Hampshire," "Stove for Cooking, Heating, and Illuminating," No. 2695), which wasn't primarily a stove at all. The drawings were entitled "Gas Retort," and the Patent Ofiice assigned it to a non-stove classification, but Walker called it his "Gas Stove." It was a small coal-gas generator bolted onto, and using the heat of, a standard square, flat stove of the kind the Woolsons had made and sold in Clermont just eight miles north. It was another example of the popularity with American stove (and other) inventors of the multi-purpose, waste-minimizing appliance, "cooking or warming a building and generating gas by the same fire." The aim was clear enough -- to bring the benefits of gas lighting within reach of the household far from any piped town gas. Whether it was ever made for sale is unknowable, or at least I haven't found any evidence yet.

And after that there is a complete gap. A class of inventive activity that had once been so comparatively important -- eight stove and fireplace patents in 1836, the peak year, about a fifth of the state total -- disappeared entirely. David Hilliard returned to Cornish, and became a gunsmith. Charles Woolson moved to Cleveland. Elijah Skinner never took out another patent. Nobody replaced them, or the other ambitious mechanics with a good idea who had been so busy during the 1830s.

The best explanation for this is the simple one introduced above: thanks in part to transport improvements, cheaper and better imported stoves invaded the up-country markets in the late 1830s, and the window of opportunity for local manufacturers swung shut, and with it the incentive to invent and patent. When stove patenting resumed in New Hampshire, in a small way, after 1850 (one or two a year), its focus and character were quite different. Almost all of them were the new class of design patents, not functional "inventions" or "improvements." They were the work of a handful of pattern makers living in Nashua, Manchester, and Great Falls, and servicing the stove foundries that were springing up in the state's leading industrial cities, often as departments of textile machinery builders. The tradition of "democratic invention" and proto-industrial manufacture in the state's hinterland was no more.

P.S. One thing leads to another -- I have the data on Vermont too, which I will work through in a similar way to the above when I have time, but here it is in map form already: basically, what it shows is very different, and much more like the normal US pattern. Vermont stove patents were usually taken out by people associated with the state's stove-making iron furnaces and foundries, or by people connected with the stove trade and living in the state's major towns and commercial centers, notably along the Connecticut River valley. In the 1830s, in particular, we see the emergence of repeat or "professional" inventors, notably Henry Stanley of Poultney, connected with what were for the time major businesses; and most of the stove patents that survive seem to have translated into commercial products that were advertised and sold. Vermont stove inventors and makers had a much larger market to operate in because, thanks to the Champlain Canal, by the end of the 1820s they were able to export to the west via the Erie Canal and the Great Lakes, or down the Hudson River to the ocean and the cities of the Atlantic seaboard and their hinterlands, as well as up into Canada. It was an entirely different environment for invention and enterprise than Woolson, Skinner, and their New Hampshire artisan contemporaries faced.

No comments:

Post a Comment

Comments will be moderated to prevent spamming, phishing, and advertising. If you wish to do any of these things, please don't waste your time and mine.