|

| The numbers of a range or stove refer to the size of the boiler holes, with other dimensions (including those of the oven) increasing in proportion. The prices quoted translate into c. $1,400-$1,900 in 2016 term, i.e. the purchase of a small range took about as much of the average 1861 blue-collar worker's wages as a comparable domestic consumer durable costing that much nowadays. These prices are very similar to those of Leibrandt & McDowell, a leading Philadelphia firm, for like products (2 or 3-boiler portable ranges) at the same time -- from $3.75 for the cheapest 7" to $8.50 for a 12" (c. $3,200). L&N also produced a new 5-boiler range "well adapted for winter or summer use" for $6 (6" boiler holes/26.5" wide) to $9.25 (8"/33.5"), i.e. $2,400-$3,700, directly comparable with a modern range cooker. This was exactly similar in layout, apart from the absence of the middle boiler hole in the back row (its place was taken by the stove pipe) to Joseph Read of Boston's Patent 26,054 of 1859, i.e. it was among the first of the modern portable ranges to compete with cook stoves in capacity, functionality, and price. |

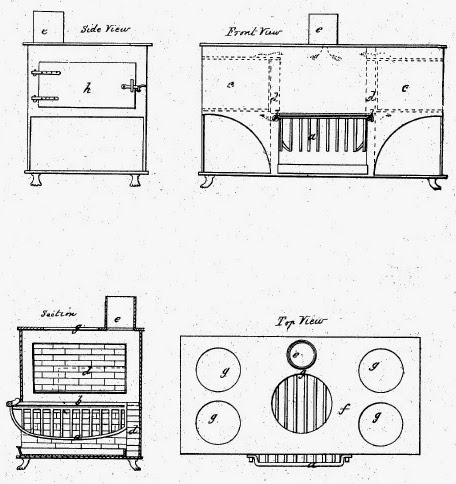

Potter's 1858 patent design shows what started out being called a "portable range," to distinguish it from brick-set, built-in ranges, though the adjective soon dropped away. (An alternative, equally revealing name was "Summer Range," i.e. a smaller appliance that could be placed on a covered porch or in an outhouse, to spare the family the heat of cooking in the kitchen of a house that was already baking.)

As we can see, it was basically just a small cooking stove rotated through 90°, and with few other modifications to its layout. The cook worked facing the stove, rather than having to stretch and reach, or move to one side or the other, to access the firebox, oven, and furthest cooking holes in the rear of the top plate. The range had a similar footprint to a cooking stove but did not stick out so far into the kitchen, so it was probably more economical of space as well as more convenient to use. It was also much easier to add to with the helpful extra features -- additional boiler-holes, hot-water reservoirs, back boilers, warming closets, warming and drying shelves above the back of the top plate -- that designers were beginning to incorporate by the middle of the century to improve a stove's functionality. The range simply needed to be made wider and a bit deeper, with no loss of usability; whereas a stove had to be made longer, and therefore to stick out further into the kitchen and be more of a problem to work around.

The American range had just one major disadvantage as compared with a standard (by the 1850s) four- or six-hole cooking stove: it only had one long side towards which people could draw up close when they wanted to thaw themselves out after coming indoors chilled from the winter outside. You could pull up a chair and warm your feet on both sides of a stove, and at the front too. A range was comparatively unaccommodating. It was also somewhat more expensive. For these reasons cooking stoves remained the appliances of choice in poorer and rural households, but in urban and small-town America ranges quickly became common, and normal by the end of the century.

Where and when did the range originate?

As with most questions about the early history of American cooking and heating appliances, no definitive answers to these questions are readily available, and we cannot even find as many material remains as we have about, for example, 6-, 9-, and 10-plate stoves, from which we can make deductions about the evolution of manufacturing techniques or intended uses. However, there is enough evidence of different sorts to enable us to hazard a guess.

A useful way of thinking about the history of the range is to ask what -- apart from being a cooking stove set against a wall rather than projecting out from it -- this appliance essentially was, in terms of its function. Viewed this way, we can think of it as a way of bringing several everyday operations in cooking and household management together in one appliance rather than spreading them out among several different ones, each requiring their own separate source of heat.

Kitchens of larger and more prosperous eighteenth-century households had a principal cooking fire for operations requiring the direct application of heat to food (toasting, grilling, roasting) or to the utensils in which it might be cooked (pots, skillets, spiders, dutch ovens); a separate brick-built baking oven, often alongside the kitchen fire, heated by building a fire within it, raking out ashes and embers when the brickwork had heated to the required temperature, and then used to bake bread when it was at its hottest, and other items as it cooled. They would also, probably, have a water boiler -- a metal cauldron set in brickwork. And they might, if particularly progressive, have what the English called a "stew stove" -- a row of small holes in a stone or later iron top, set waist-high on brickwork. Each had an iron basket within it to take an individual fire (probably a shovelful of embers and coals from the main hearth) beneath it. This was used for more delicate cooking operations in households prosperous enough, and with a sufficiently Frenchified taste, to need and afford them. When late 18th-early 19th century British and American cookbooks refer to the use of a "stove," this is what they mean.

|

| English illustration of a small (2-hole) stew stove, 1772 Reconstructed stew stove in kitchen annex at Ham House, Surrey, showing iron liners for cooking holes. |

|

Reconstructed stew stove with ?iron top in main kitchen at Ham House, Surrey

|

Stew stoves were not an English invention -- they were probably an adaptation of the French potager, whose antecedents stretched back to Roman times -- but they were the most likely models for those in some prosperous North Americans' kitchens. Some of these survive from the early national period in the houses of the rich, or have been reconstructed by archaeologists and preservationists in more modern times, and they show these arrangements quite clearly. The best documented is probably Thomas Jefferson's at Monticello, dating from (accounts differ) before 1796 but after his return from France in 1789, or 1809, after the installation of similar apparatus in the President's (now White) House for his successor James Madison. [Sources: Justin A. Sarafin, "Like Clockwork: French Influence in Monticello's Kitchen," in Damon Lee Fowler, ed., Dining at Monticello: In Good Taste and Abundance (Chapel Hill: University of North Carolina Press, 2005), pp. 19-28, for full description and 1796 date at p. 23; Dave DeWitt, The Founding Foodies: How Washington, Jefferson, and Franklin Revolutionized, p. 187 for 1809].

|

| Reconstruction of Jefferson's kitchen at Monticello, showing 6 or 7 holes of the 8-hole stew stove, the "set kettle" (water boiler) in the corner, cooking hearth with crane, and bake oven. High quality versions available on Flickr -- Top, Bottom. |

A more ordinary and (at the time of the photograph, in 1913) quite well preserved urban kitchen, surviving from an eighteenth-century house in Quebec City, shows the arrangement in some ways even better: the potager to the left of the fire, the bake oven (with a water container placed on the hot shelf above it) to the right, a water boiler (with part of a later iron stove sitting on top) in the corner.

|

| From Marcel Moussette, Le Chauffage Domestique au Canada: Des Origines à l'Industrialisation (Montréal: Presses Université Laval, 1983), p. 130. |

A similar but probably slightly later (Federal period) New England example incorporates the first piece of genuinely new technology to enter a few North American kitchens -- those of the upper class, or businesses (taverns) and institutions cooking on a large scale: the Rumford Roaster, a fuel-saving oven built according to Benjamin Thomson (Count Rumford)'s principles.

|

| Sandra L. Oliver, Food in Colonial and Federal America (Greenwood Press, 2005), p. 100. |

The challenge for the inventors and makers of the first American ranges was to make these facilities hitherto only available in the kitchens of the wealthy accessible to a wider range of customers, and at the same time to improve them, by bringing the different functions (cooking by direct and indirect heat -- toasting, grilling, roasting, baking, and boiling; heating water; and space heating) together into a single appliance. In order to appeal to a wider market these appliances had to be (1) available -- a network of designers, manufacturers, installers and suppliers needed to develop, at first in the major seaport cities, but reaching out from these bases by mid-century; (2) serviceable -- appliances had to be tailored and then improved, by experience, to meet customers' changing needs, and to satisfy their expectations about, for example, fuel economy; and (3) affordable -- in the beginning, ranges were customized artisan products, priced accordingly, and only appealing to the rich or to those cooking on a large scale (boarding houses, hotels, restaurants, public institutions). To grow the market, an increasing proportion of a range's components needed to be somewhat standardized and turned into factory-made and ideally factory-assembled goods.

There was one final challenge that needed to be overcome, even within the markets of the port cities, before the range could become a mass-consumption good, and that was the one the portable range, the true antecedent of the common late nineteenth and twentieth-century range, began to address: they had to be (4) movable -- a function of a range's weight, construction (as a free-standing unit or as a built-in appliance), and robustness. A characteristic of the domestic real estate market in the cities, particularly New York, was the prevalence of short-term tenancies and regular, even annual, removals from one house or apartment to another. Even relatively prosperous tenants or mobile owner-occupiers were unable or unwilling to make the large fixed investment in kitchen equipment that a built-in range represented. The free-standing stove suited their lifestyles much better. Only when makers could produce ranges that were as transportable as a stove, or sufficiently cheap that landlords were prepared to install them as fixed equipment, would ranges become ubiquitous. [Elizabeth Blackmar, Manhattan for Rent, 1785-1850 (Cornell Univ. Press, 1991), on tenures.]

|

| H. Mosler, "Just Moved," lithograph by A. & C. Kaufmann, 1873. Original 1870 oil painting at the Met. The stove is a six-boiler anthracite burner. |

The British Kitchen Range and Kitchener -- A Model for Americans?

An interesting question, to which I can have no definite answer, is whether (or rather when, and how much) early American range designers and builders were influenced by 18th and early 19th century British example: the development, in a largely deforested country where the use of coal for domestic fuel was already widespread, and with a much more advanced iron industry than the early United States, of the typical British kitchen range, with an oven and a water boiler either side of an open cooking fire in the middle.

|

| Cast-iron Kitchen Range, Lunesdale Bakery, Kirby Lonsdale, December 2014 [high-quality version] |

|

Cast-Iron Kitchener, Lindisfarne Castle, Holy Island, Northumberland, October 2014 [high-quality version]. The fact that this range and the one before were probably early C20th models does not matter much, given that there was so little technical progress in British range design and manufacture (see below).

|

The first British patents for this layout were obtained in the early 1780s, and the first which covered the top of fire (and came to be known as the kitchener) in the early 1800s. [David J. Eveleigh, Firegrates and Kitchen Ranges (Princes Risborough: Shire Publications, 1983, pp. 16-28.] All of these British ranges and kitcheners were built into the existing fireplace opening or chimney breast, but a "portable range" like later American types was patented in 1815, though it does not seem to have caught on until the middle of the century when American ranges were shown at the Great Exhibition in London, after which they were known and sold in the British market as "American ranges" even when manufactured locally.

In the latter case, we have very clear evidence of American influence -- the major British manufacturer of these products, Smith & Wellstood of Falkirk, was established by a man who had worked as a stove dealer in the United States before returning home to make and sell pirated versions of American designs, which were by then more advanced than their British equivalents. But there is no similar proof that early 19th century American range builders started out by following British models rather than just reaching a similar destination by their own independent path. However, given that the early American range was a product whose manufacture and use was almost confined to the major port cities of Philadelphia, New York, and Boston, it would be very surprising if there had been no influence at all, however unacknowledged, and whether conveyed via importation of goods, travel and observation, immigration, or simply by reading. [See e.g. Mrs William Parkes, Domestic Duties: Or, Instructions to Young Married Ladies, on the Managementof their Households (New York: J. & J. Harper, 1829), pp. 169-70 -- the third American edition of a work first published in London in 1825, taking a range for granted as a centerpiece of the modern kitchen, and extolling its advantages.]

But the evidence is that by mid-century the American ranges that were most like their British counterparts -- large, heavy, and built-in -- were already more technically advanced; and for the portable range and the appliances that developed from it, there was no effective British precedent. The state of the art in British mid-century range design is well summarized in John Sproule's catalogue of the 1853 Irish Industrial Exhibition (a follow-up to the larger and much more celebrated Crystal Palace Exhibition), quite critical of English range makers' (and customers') devotion to very conservative design principles, including huge, hungry, smoky open fires. American range designers made far more progress within a couple of decades of the first significant range production in the United States in the 1830s than their British counterparts had made, or would make, in a much greater period of time.

|

| Sproule gave this crude little portable range and its maker, Benham's of London, the highest praise: "Their cottage range was among the best of the articles of its class from its completeness, and the large amount of accommodation which it afforded. ... it is not necessarily a fixture and ... it merely requires a pipe to connect it with the flue to admit of its being placed anywhere that may be convenient The quantity of fuel consumed in it is inconsiderable, compared with what is ordinarily required. A suite of cooking utensils may be had with the range which makes it an admirable article for the emigrant or cottager; the whole comprising the means of cooking comfortably for a small family." But the cheapest and simplest American portable range was already far more attractive and usable than this. [For another expert but less critical report on mid-century British practice in kitchen design and equipment, see Thomas Webster & Mrs William Parkes, An Encyclopaedia of Domestic Economy (New York ed. of English original, 1855), pp. 843-47.] A decade of further rapid progress later, the authoress of Dinners and Dinner Parties reached the only sensible conclusion, one which seems to have escaped most of her contemporaries: "[P]ersons who study economy and cleanliness" could escape the "expensive ... [British] kitchen range" with its "destruction of tons upon tons of coals, its dirt, its soot, and its waste," by adopting American-style ranges, available in London but still not yet popular. The fire chamber occupies the centre of the range, the heat from which passes to the right and left under the different pots, kettles, or boilers, which fit into the hot plate, and then descending completely encompasses both ovens, and imparts an uniformity of heat never before attained, so that joints, pastry, &c do not require that constant turning which is found necessary in many of the most expensive ranges in use. The fire chamber is fitted with fire-clay linings, and the hot plate is so arranged and divided off into sections as to render it perfectly secure against fracture or cracking from over-heating. The flues of the range, after making the circuit of the two ovens, meet and pass out at the back, from whence the necessary connexion with the chimney may be made with either a sheet iron smoke pipe or a brick flue. The arrangements for clearing out the flues are so simple and complete that it may be done thoroughly in a few minutes at any time. As we will see below, The Gentlewoman was describing a recognizable American range, incorporating the fruits of three decades of increasingly imitative and competitive innovation by designers in the seaboard cities which had delivered, by the eve of the Civil War, a good mass-market product. (Slightly confusingly, the above clear description is illustrated with a picture of an American-style stove in an English kitchen fireplace, with a hot-water cylinder beside it. But the text makes it plain that something like John Treadwell of Albany, NY's "Range or Stove" of 1860, Patent 30,013, is what she is actually talking about.) By the 1870s, knowledgeable American observers were even more brutally dismissive of their British counterparts and their products, which seemed to have experienced no improvements in at least a generation. British ranges, with their "ungainliness of shape and general ugliness," were "as hideous as their grates and open fire places are beautiful." They had small, slow ovens, and were as inefficient as they were uneconomical. "Awkward, ugly and inconvenient to a degree unapproached in any other class of goods we know of, [English kitcheners] stand at least half a century behind the American standard of excellence." ["English Stoves," The Metal Worker 3:21 (22 May 1875):4.] So if there was any direct British influence on American range design in the 1820s and 1830s, by mid-century its time had certainly long passed, and it is reasonably safe to assume that the evolution of American range design and construction which the remainder of this post will examine was an almost entirely homegrown process. |

The Kitchen Range in the U.S. Patent Record

As usual, and for all of their imperfections, surviving patent records provide the best way of reconstructing the development of this stove type in the United States. Few kitchen ranges from the Early National Period survive, either in historic houses or museums, and newspaper or other advertising (e.g. makers' broadsides and catalogues) is rare before the 1830s and not very common until the 1850s, so the patent record provides a necessary fallback.

William Gamble of Washington, DC., patented a "Distillery and Kitchen Range," number 1492X, in 1811, the first to use the name in its official title, but that is all we know -- it was destroyed in the Great Fire of 1836, which wiped so much of the record of the first 45 years of American invention. Gamble (1758-1833) was a member of an Anglo-Irish merchant family who emigrated from Dublin to the Colonies, served with the rebel forces in the struggle for independence, and then pursued a long and not very successful career, including a failed attempt to set up a distillery in Niagara, before his move to Washington in the 1800s. Did Gamble bring part of the idea of, or at least the name for, his kitchen range to America with him, or did he invent it there? Probably we will never know.

Destruction by fire was also the fate that befell all but 27 of the c. 230 patents for cooking and heating apparatus issued before 1830, so we cannot tell whether any of them may actually have been for what we would call "ranges," though their authors used another term. One partial exception is Samuel Dickey of Oxford, PA's "Stove," Pat. 670X of 1806, and that is only because we have his "Description of a Kitchen Stove" in the Memoirs of the Philadelphia Society for Promoting Agriculture, Vol. 1 (Philadelphia: Jane Aitken, 1808), pp. 290-295.

Dickey's stove (which I wrote about here more than four years ago) was a hybrid device -- it seems to have married the layout of iron ovens above a fire-box from Oliver Evans's "Philosophical and Ventilating Stove" of 1795 with a cast-iron cooking hearth possibly derived from the suppenherd, the Pennsylvania German version of the potager. Unlike the stew stove, whether in its traditional or Rumfordized versions, Dickey's three cooking holes did not have their own independent fires: they were instead heated from the single fire beneath the oven. Dickey's device looks like the product of independent invention, or at least synthesis (enough to persuade the U.S. Patent Office and courts of a device's originality), designed without any obvious knowledge of British precedent, and lacking any clear legacy to subsequent range designs.

The first patent for what did look more like a (later, portable) range, though, like Dickey's, it did not use that term, has also not survived, and did not seem to serve as a model for later American ranges either, was Charles Postley of New York's "Cooking and Heating Stove," X2074 (1814). Postley was a successful inventor, manufacturer, and dealer, remaining in the business for another thirty years, but there is little evidence that his pioneering idea of rotating a free-standing cooking stove through 90° was imitated at the time, though it was much more versatile than most that followed it for the next couple of decades, even including a copper water-heating coil. Postley's device, like Dickey's, looks to be all-American, with no clear ancestry and no immediate progeny.

|

| "Postley's Patent Cooking Stove," The American Magazine 1:9 (Feb. 1816): 326-7. For more about this, see this blog post. |

George Youle, also of New York City, patented a "Fire-Hearth Range or Galley," 3087X, in 1819, but like William Gamble's its record was also consumed in the Great Fire of 1836. This is a pity. As the title suggests, Youle was a specialist "caboose" (ship's stove) maker (see this blog post), so it would be interesting to know if his "Fire-Hearth Range" was an adaptation of galley stove design to meet the needs of customers on land too. But we can only guess.

In the same year Jonas and Simon Gleason, Philadelphia hardware manufacturers, did not patent (Jonas's only patent was in 1814, for making screws), but did advertise and sell, something that was not quite a range, but performed many of the same functions. It might, perhaps, not have been their patent, except by purchase, but a device based on the still valid 1812 patent of John Bouis, the "snuffy old" Baltimore tinsmith, sheet iron worker, and cooking and heating appliance maker and inventor, for a steam stove, Patent 1632X; or it might have been a rip-off of a British appliance imported and sold the previous year.

|

| Bouis's Patent. |

What this advertisement tells us is that there was already a market, notably among households, businesses, and public institutions cooking on a large scale, for technological solutions to the challenges of catering and domestic management -- or at least the Gleasons thought there was, and given that they stayed in the business for another three decades they must have been right.

The market may have been developed by imported British technology:

|

| Paxton's Philadelphia Directory, 1818. |

But this market can only have been a narrow one: the smallest "Steam Kitchen," for a family of four to six, cost $43 ($30,500 at 2016 prices, using the "Average Production Worker Compensation" method of comparison); the largest, for a "family" (household, including servants) of 18 to 25, cost $92 ($65,300). These were somewhat cheaper than Slater's prices on imported goods -- $55 to $200 "and upwards" for "five to five hundred persons" translates into c. $40,000-$140,000 plus, i.e. unaffordable by and in fact not intended for any but the most prosperous households, with abundant discretionary spending power. Prices like these confined the demand for the Gleasons' and other similar products, perhaps including Bouis's and the the Youles', to consumers with ample resources and either the luxury of choice or the pressure of necessity -- commercial or institutional caterers. Ranges were little different, at least in the beginning.

* * *

Through the 1820s there were no further range patents, and a careful search of Philadelphia and New York City directories shows nobody describing himself as a range maker until Charles Tozer in New York in 1835, after which the numbers of these specialist members of the stove-making community slowly increased. Not coincidentally, the early/mid-1830s is also when we begin to see a steady trickle of range patents. None of these appear to have been influenced by Dickey's, Postley's, or Bouis's, work, and it was at this period that imitation of, or at least convergence with, British range and kitchener design is most apparent, though evidence of direct influence is lacking.

What stimulated this new wave of American "invention"? Most probably the same thing that had led to the development of the British range and kitchener decades earlier -- the beginnings of the changeover from wood to coal as the predominant fuel of urban America, requiring new appliances (at the very least, a fire with a grate) to burn it in. As James Vaux of Philadelphia's 1826 design for an anthracite-burning cooking grate demonstrated, building one into an existing kitchen fireplace left plenty of space either side. American range makers promptly began to fill it, mostly following British precedent at first, but soon departing down their own, more progressive tracks.

|

James Vaux, "Remarks upon the Use of

Anthracite, and Its Application to the Various Purposes of Domestic

Economy," The Franklin Journal, and American

Mechanics' Magazine 2:5 (Nov. 1826): 292-5.

|

According to the 1835 New York City directory, Jennings was a moulder. The text of his patent is less revealing than the picture, and there is unfortunately no key to the letters marking different features of the range. It seems partly inspired by Oliver Evans's 1795 design, because it combined the functions of a cooking range with those of a warm-air furnace capable of heating "every apartment in the house, at any agreeable temperature, by conducting the hot air through pipes or flues." It performed "all that is required for culinary purposes (viz) Roasting, Boiling, Baking, Frying, Broiling, Stewing &c." It was designed to run on any fuel, though Jennings preferred anthracite, just then coming into use in the city. It looks as if the range had hot-water reservoirs either side of the top plate and inside the brick-lined back wall -- otherwise, what are the faucets for? The round-headed Norman arched door in the brickwork was probably for a closed firebox, with niche in the base for shovelling out ashes; the upper, Gothic arch was probably for the oven. It is possible that there may also have been an oven between the firebox door and the hearth, its door bearing Jennings's name and patent details. The top plate carries two large steamers. An interesting feature is the glazed windows and hood over the top of the stove, probably designed to minimize cooking smells in the house by carrying them away up the chimney, but the description is as silent about these as it is about the various knobs marked b in the front and top plates which probably controlled dampers for directing the heat to one boiler or another, or to the upper oven. [hjh -- more here or later on kitchen smells?]

A. Savage, Pottsville, PA. Anthracite-Coal Stove, Pat. 6026X, 1830.

This is another lost (burnt) patent, but there is a good description of it in the Barnstable Patriot, 24 Aug. 1831, p. 2, making it sound very like a conventional British range or perhaps kitchener (the "hot hearth" may refer to the iron plate on top of the fire):

David Gassner, New York City. Coal Cooking Stove, Pat. 7163X, 1832.

In 1835, J. & M. Gassner were tinsmiths -- craftsmen very close to the early stove trade, for which they made utensils and "funnels" (chimneys), and did sales and installation. David was presumably a family member. The range he patented was designed to burn anthracite in its open basket grate, and looks very similar to a British kitchener, except that it was free-standing, like a stove, not built-in, and sat on its own cabriolet-style stove legs. There were ovens on both sides of the central fire, accessed from each end, and a metal plate over all, pierced by four cooking holes and one large central hole for grilling. Its peculiar advantage was said to be the "steady and uniform degree of heat which may be applied to all parts of the stove at the same time." It could be built of cast or sheet iron, the latter of which "whitesmiths" (sheet metal workers) like the Gassners could shape and assemble.

Josiah W. & Eli Kirk, Philadelphia, PA. Heating and Cooking Stove, Pat. 7735X, 1833.

The Kirks' original patent was actually for a square, neat anthracite stove with a single oven over the fire and four boilers. What they seem to have done over the next few years was to develop it into an early example of a "portable range," not unlike Gassner's, with the optional extra of a "perpetual boiler" attached (like Postley's twenty years earlier), to provide "a full supply of hot water for bathing and culinary purposes."

(It is possible that I am not reading the above engraving of their stove's evolved form properly: are the spaces either side of the firebox and oven perhaps simply air-heating chambers fronted by grilles? There was an air-heating jacket in the original stove too. In that case, even though the 1837-1839 version was a stove with a rectangular shape placed parallel with the wall behind it, it might not actually have been a range at all, simply an interesting stove variant, and this might not be the first range advertisement that I have come across.)

Eliphalet Nott, Schenectady, NY. Kitchen Range for Using Anthracite Coal, Pat. 8792X, 1835.

A strange-looking invention by America's premier stove designer, the Reverend Dr Eliphalet Nott, President of Union College. Really just a free-standing cooking stove which could be built with its four cooking holes set out in a row, like those on a stew stove, rather than in the usual square formation; not a proper range, lacking an oven.

Elijah Skinner, Sandwich, NH. Cooking Stove, Pat. 8889X, 1835.

Skinner was also quite a prolific stove inventor (see this post), despite the fact that he lived in the interior of the least economically dynamic state in New England, and his "stove" actually looked much more of a range, with three cooking holes and an elevated oven, a layout that became very common in New England. Skinner's range was made to be built into existing fireplace openings and, unlike most of those being designed in the 1830s, was not intended for anthracite fuel (there is no grate, and a very large firebox).

T.B. Smith, New York City. Cooking Range, Pat. 9063X, 1835 -- Destroyed by fire, 1836. Smith was a moulder.

G. Johnson, Philadelphia, PA. Kitchen Range, Pat. 9676X, 1836 -- Destroyed by fire, 1836.

W.W. Parrott, Boston, MA. Cooking Range, Pat. 142, 1837.

Another recognizably British-pattern, brick-set cast-iron range, to be built into an existing fireplace, with an open grate and an oven either side of the fire -- a transitional design, for customers just beginning to move away from fireplace cookery. Roasting was to be carried out in front of the open fire, pots and pans to be suspended over it, i.e. there were no cooking holes in the top plate over the ovens. It was equipped with a grate adaptable to all fuels, but Parrott recommended anthracite as the best.

Elijah Skinner, Sandwich, NH. Cooking Stove, 429, 1837.

This was not described as a "portable range," though it easily could have been -- Skinner's stove was installed in a fireplace opening, but stood free of the back wall. His patent describes several different layouts, of which the first (illustrated above) makes it clearest that this was essentially just a wood stove with an oven behind and below the fire and three cooking holes in the top plate, fitted sideways rather than lengthways. Most unusually, Skinner also provides dimensions, so we can visualize his stove's size -- c. 3'6" long by 16-18" wide, which allows us to at least estimate its height from the drawings (c. 2'6" on its low brick plinth).

John Morris, Derby, CT. Cooking and Warming Stove, Pat. 455, 1837.

An idiosyncratic design, made to be installed in an existing fireplace opening, with a large, raised oven, and three small fire-grates side by side, each of them with a cooking hole in the iron plate above it. They could be used separately, like the individual holes of a stew stove, traditional or Rumfordized, or all together, and were intended for anthracite as well as other fuels. Like Jennings, and following Oliver Evans's original plan, the stove was designed to heat the upper floors of a house with warmed air, as well as to do the cooking. A John Morris, then of New Haven, had also invented a "Cooking Apparatus" in 1812, Pat. 1809X (burnt 1836), and "proved himself to be of great advantage to his race by several [other] inventions, specially his faucets and patents for putting up meats" -- a "Box Boiler" in 1812 and apparatus for "Distilling and Boiling Liquors" in 1816. [Mathews, Descendants of Governor Thomas Welles of Connecticut and His Wife Alice, p. 935] If this was the same John Morris, he was by this time an old man (his wife was born in 1766), but experienced in designing and building heat-using devices used in food preserving.

Samuel Pierce, New York City. Mode of Constructing Flues, &c., of Kitchen Ranges, Pat. 613, 1838.

This was the first recorded patent by a man who went on to become one of the most influential stove inventors in mid-century America, active until the early 1870s. Pierce, b. 1812, was the youngest son of Samuel Pierce, the tinsmith of Greenfield, Massachusetts, and younger brother of John J. Pierce, proprietor of the town's Franklin Furnace and a stove inventor since at least 1822, the year in which he took out a (lost) patent for an open cooking stove, No. 3473X. In 1833, when he turned 21 and probably completed his apprenticeship, Samuel moved to New York City and opened a stove store on Lower Broadway [Richard Edwards, ed., New York's Great Industries. Exchange and Commercial Review, including also Historical and Descriptive Sketch of the City, Its Leading Merchants and Manufacturers (New York: Historical Publishing Co., 1884), p. 102]. By 1835 he was already describing himself as a patent range manufacturer, a description he shared with none of his competitors [Subscribers' List, Journal of the American Institute 1:2 (Nov. 1835): 40].

Given that he did not have any patents in his own name at that time, it is possible that what he was doing -- and the reason he had moved to the city -- was to manufacture and/or sell goods to his brother's old patent, but for a much larger market than the Upper Connecticut valley offered. Alternatively, he may have been manufacturing another inventor's patent, under licence -- one of those lost in the 1836 Fire. Or he may simply have been making an unjustified claim, for purposes of self-promotion -- not uncommon in the early American stove trade.

The range he made and sold looks to have been a modification of a British-style kitchener, like Gassner's, but built-in rather than free-standing, with the oven moved above and behind the fire like Skinner's, and the water boiler to the right probably heated by its own flue or perhaps a pipe running through the grate. The iron "cheeks" either side of the fire served no purpose except to support the top plate -- there were no ovens behind them, something only added by the time of his 1838 patent. A probable attraction of the elevated oven layout is that it could be heated effectively by a simple and direct smoke flue rather than by radiation and conduction through the side plates of the grate, the method adopted by Gassner, or the increasingly complex downdraft flue systems adopted by later inventors who wanted to site their ovens at ground level, below the hob. The obvious disadvantage was that the cook had to reach and stretch above the fire in order to get at the oven.

Note the large spaces between the bars on Pierce's grate: like Gassner's, it was made for customers new to burning anthracite, who thought it best or even necessary to buy and use it in large lumps. This was a tremendously wasteful practice, and a carryover from New Yorkers' previous habits in burning bituminous coal from Virginia or Liverpool sea-coal.

Given that he did not have any patents in his own name at that time, it is possible that what he was doing -- and the reason he had moved to the city -- was to manufacture and/or sell goods to his brother's old patent, but for a much larger market than the Upper Connecticut valley offered. Alternatively, he may have been manufacturing another inventor's patent, under licence -- one of those lost in the 1836 Fire. Or he may simply have been making an unjustified claim, for purposes of self-promotion -- not uncommon in the early American stove trade.

The range he made and sold looks to have been a modification of a British-style kitchener, like Gassner's, but built-in rather than free-standing, with the oven moved above and behind the fire like Skinner's, and the water boiler to the right probably heated by its own flue or perhaps a pipe running through the grate. The iron "cheeks" either side of the fire served no purpose except to support the top plate -- there were no ovens behind them, something only added by the time of his 1838 patent. A probable attraction of the elevated oven layout is that it could be heated effectively by a simple and direct smoke flue rather than by radiation and conduction through the side plates of the grate, the method adopted by Gassner, or the increasingly complex downdraft flue systems adopted by later inventors who wanted to site their ovens at ground level, below the hob. The obvious disadvantage was that the cook had to reach and stretch above the fire in order to get at the oven.

Note the large spaces between the bars on Pierce's grate: like Gassner's, it was made for customers new to burning anthracite, who thought it best or even necessary to buy and use it in large lumps. This was a tremendously wasteful practice, and a carryover from New Yorkers' previous habits in burning bituminous coal from Virginia or Liverpool sea-coal.

Pierce's original "patent range" (1833), lacking the ovens either side of the fire in his 1838 model, and, probably, the distinctive flue arrangement. ["Pierce's Kitchen Range and Cooking Apparatus," Mechanics' Magazine, & Journal of the Mechanics' Institute 2:2 (Aug. 1833): 105-6.]

In 1838 he finally patented his own, by then prizewinning, brick-set, anthracite-fuelled cooking range ["List of Premiums Awarded by the Managers of the Ninth Annual Fair of the American Institute, held at Niblo's Gardens, October, 1836," Journal of the American Institute 2:2 (Nov. 1836): 85-95 at p. 87] which other New York firms made for him. He also sold manufacturing rights outside the city [Proceedings of the Second Annual Fair of the Ohio Mechanics' Institute: Held during the Third Week in June, in the City of Cincinnati (Cincinnati: R.P. Brooks, 1839), p. 12]. According to the city directories, Pierce's stoves were at first manufactured by a partnership of two local artisans, David Lockwood, a grate-setter, and Henry Andrews, a stove-builder; between 1839 and 1840 the partnership changed to Pierce & Lockwood, the two men having separate stores on Broadway and Fulton.

Pierce's patent range had three ovens, one either side of the fire and a larger one, with three shelves, heated from the smoke flue; five cooking holes in the top plate of the range; and a water boiler, with a tap, to the left of the range, which must have had its own flue too, and a damper to control it, or a heating coil behind the grate. Like most ranges at the time, this was designed for large, prosperous households or commercial cooking (restaurants, hotels, institutions, etc.). The metal parts were made by blacksmiths and iron founders, and then assembled and installed within the kitchen alcove that used to be occupied by the old cooking fire, or built into new houses. Pierce's ranges were expensive, customized products, and represented a large and immobile capital investment. They were not seeking, and would never find, a mass market. Pierce and the makers and installers he licensed made their money from a high margin, not large volume.

Despite these limitations, Pierce's business evidently grew. By 1842 he was a sole trader as a patent range manufacturer on Fulton Street, and his old partner Lockwood was once again independent too. In 1843 he decided to devote himself to stove invention full time, leaving the New York City business in the care of an older brother, George, who would continue to sell what his brother invented from his store, which he moved back to Broadway, until at least 1856. Samuel moved first to Peekskill, where there were foundries and pattern-makers to work with and “a pleasant place of residence of my family” [Pierce testimony in Report of a Trial, pp. 20, 24 (quote)]. In 1845 he moved to Troy, just eighty miles west of Greenfield, where he still had a farm, and stayed there for the next couple of decades, producing twenty-four original patents for heating and cooking stoves and ranges in a thirty-three year inventing career.

Lockwood Range in the Riker Homestead, Queens, New York. Historic American Buildings Survey Collection, Library of Congress. This seems to have been a design of Lockwood's own, with a Jordan Mott-style fuel feed door [see this post] above the firebox, drop-down Barrows-style oven doors (see below), and two additional offset elevated ovens or warming closets. Recent photographs of the kitchen seem to indicate that this range is no longer in situ, and probably n'existe plus.

A large built-in kitchener similar to Pierce's, i.e. this sort of brick-set, British-style range, looking like a grand cast-iron dresser, was what the market expected and required. Barrows's USP was that his oven doors folded down, for ease of access -- a feature covered by a patent he obtained in 1837, no. 366; his patent claim in this detailed, well-illustrated application was for the design of the flues for distributing heat to all of the ovens, and the dampers for controlling it. The range included a vent for extracting the steam and smells from the cooking vessels on the top plate into the chimney. Barrows (1797-1858) was a member of a group of South-East Massachusetts iron founders making hollow ware and stoves -- the interrelated Barrows, Savery, Ellis, and Bowers families. [Source: Jim Fuchs.]

Herbert H. Stimpson, Boston, MA. Cooking Range, Pat. 1,515, 1840.

|

| Stimpson's Boston Directory, 1832-33, back cover. |

The Stimpson brothers, Herbert (originally a tinsmith) and Frederick, had been in the stove trade in Boston since at least 1828, buying their castings from New Jersey furnaces and doing their own finishing, assembly, and sales from their city centre "factory." As we can see from the above advertisement, at the start of the 1830s they had a wide but quite traditional product line which did not include any kitchen ranges, just the iron parts of brick-built bake ovens and boilers that equipped some of the larger and more prosperous urban kitchens and might be thought of as predecessors to the range. A few years later they joined the small group of range designers and builders themselves.

Their first patent may have been in 1840, but by that time they were already quite experienced, their products well known. In December 1838, for example, their castings supplier, New Jersey iron master David Cooper Wood, wrote to Herbert that "Your brother continues amongst us [in Philadelphia], for a most benevolent purpose, to provide us with the means of good living for having good provisions well cooked. And I presume his exertions will meet with the desired success -- As your Ranges are becoming very popular & when fully understood will come into general use." [Wood to Stimpson, 4 Dec. 1838, Wood Letterbooks].

The Stimpsons' range was quite like Pierce's original design, in that its only oven was in the chimney breast behind and above the fire. This arrangement, while hard on the cook, who could only reach the oven across the top of the fire, was probably a result of the difficulty of heating evenly ovens either side of the fire, if they had to depend entirely on conduction through the iron plate separating the oven and the fire. This is mostly conjecture, but it is informed by unfortunate experience in trying to bake bread 40 years in a Welsh cottage range whose small oven was heated in this way, as well as by observations in later patents on the problems their inventors were attempting to overcome. It would also help explain why other early range designers, like Barrows and Pierce, always highlighted the importance of their flue designs, which made firebox-level ovens more practicable. The Stimpsons' USP for this first range was the circulation of flue gas in two cast columns either side of the range, making the appliance more effective in heating the kitchen as well as just doing the cooking, or so they said. This is not unlike Elijah Skinner's 1835 design.

|

| Directions for Using Stimpson's New Patent Radiating and Hot Air Cooking Ranges, n.d., Historic New England Ephemera Collection. |

The emphasis on using a range for space heating, which we find in several other early patents, raises an interesting question about how designers responded to users' requirements. It is possible that early ranges, though they would impress later makers and customers as extraordinarily heavy on fuel, were too fuel-efficient for users accustomed to the amount of heat thrown out into the kitchen and the rest of the house by an old-fashioned cooking fire. Designers thus attempted, not just to get more usable heat out of the fire, but to employ more of this heat in warming the air rather than just doing the cooking.

Ebenezer Barrows, Mattapoisett, MA. Kitchen Range, Pat. 1694, 1840.

Barrows's second range patent once again included his fold-down doors and three ovens. A distinction between this range and his 1839 model is that the lower ovens in this model were supposed to be heated simply by radiation from the cylindrical fire chamber D rather than via controllable heating flues too. The only heat control in this range involved sliding shutters to close the openings E either side of the fire chamber.

Barrows's market was not confined to Massachusetts. Samuel Lloyd, running one of the oldest firms of stove dealers in Philadelphia, advertised Barrow ranges to his customers from 1839 onwards:

|

| McElroy's Philadelphia Directory, 1840, advertisements p. 50. |

Joshua Grime, Beekmantown, NY. Domestic Oven, or Apparatus for Cooking (Cooking Closet), Pat. 1918, 1840.

Not described as a range by its designer, and a side-branch or dead-end in the process of innovation, but included here simply as an interesting example of an upcountry artisan's attempt to do what urban range designers were succeeding in doing, i.e. enabling households to acquire a cooking appliance built into an existing fireplace opening and enabling them to bake, boil, or roast with a single fire.

Nathan P. Kingsley, Boston, MA. Cooking Range, Pat. 2,310, 1841.

Also outside of the main line of range development, but interesting as another attempt to turn a range into a dual-purpose device, heating air to warm other rooms in the house through convection flues. Kingsley's aim was to achieve this in a way guaranteeing "that the air shall not be charged or mingled with the effluvia, which are necessarily produced by the various cooking operations." Here, too, the designer was responding to the perceived needs of customers in the early years of the changeover from fireplace to range cookery. An open fire in an enormous hearth took most of the smells of cooking up the chimney; stove or range cooking left them in the kitchen, and permeating into the rest of the house. Kingsley and some of his contemporaries looked for a work-around for this problem, and the consumer resistance it caused.

Abram Spaulding, New York City. Cooking Range, Pat. 2,354, 1841.

Abram Spaulding showed up in the 1840 city directory as a "smith." His patent was another large brick-set British-style kitchener, similar to Pierce's with which it was a direct competitor. What distinguished it was its much more complicated internal arrangements and greater cooking capacity -- two fireboxes A and a shelf in front of them to carry a "tin kitchen" (reflector oven) for roasting meat; an integrated boiler which did not just heat the hot water tank to the left of the range but also a rising pipe z which warmed upstairs rooms by steam; three large cooking holes and three ovens above the whole width of the top plate; and an air heater, so that the range could serve as a warm-air furnace as well as for a primitive form of steam heating. It took four pages of detailed drawings to describe the internal arrangements, including a complicated system of flues and dampers to make the system controllable. Spaulding's innovations extended to include mounting his sliding oven doors on rollers running in grooves, to minimize friction.

John Brereton, New York City, Cooking Range, Pat. 2,569, 1842.

Brereton was a mason, i.e. like Spaulding he was one of the artisans who constructed and installed ranges rather than, like Pierce, Barrows, and the Stimpsons, somebody with his roots in the foundry and stove trades. His "Housewife's Assistant" was a much cruder device than Spaulding's and, as their different craft backgrounds probably explained, basically brick-built with far fewer iron parts. It was a "cheap and simple apparatus, which may serve conveniently for the purposes of a common fire place or grate for warming an apartment, and at the same time, serve with equal convenience for all the common culinary purposes, having also, due regard to the greatest economy of fuel." It had an open basket grate for burning anthracite or perhaps still bituminous coal, with no boiler, just two cooking holes in the iron hearth above the fire, and an elevated oven in the chimney, whose only moderately interesting feature was a double bottom with an insulating air space between "to prevent articles being baked in the oven from burning at the bottom," something Brereton had to exclude from his patent claim because it was quite unoriginal.

Brereton's range is mostly worth looking at for showing what an entry-level, craftsman-built device, simpler than any British range or kitchener, was like -- for less wealthy households wanting something similar to the traditional cooking fire but a bit more serviceable. It is quite unlikely that any of those he installed would have survived for long without being replaced by something much more versatile.

William Beebe, New York City. Cooking Stove, Pat. 2,710, 1842.

Beebe described himself as a "manufacturer" in his patent application. In the 1842 city directory he described his business as simply "stoves," but in 1843 and until 1854 he changed it to "cooking ranges," so we can assume that his decision to specialize in supplying the growing demand for these new and costly appliances was successful. Beebe's range was as different from Brereton's as chalk and cheese -- a grand iron kitchener with two large ovens and six cooking holes, the central two of which and the oval plate in which they were fixed could be removed entirely for grilling over the fire.

The essence of Beebe's all-iron range, designed to fit into a large cooking fireplace but not built-in or part-brick like most of its competitors, was its internal arrangement of flues and dampers to heat the ovens evenly and give the cook greater control over the heat. This is what it enabled it to move the ovens to ground level. Beebe's device was not intended to serve as a warm-air furnace too -- presumably households wealthy enough to be able to afford it would already have one installed in the basement. Instead, the large flap x above the range, controlled by handle y, was a vent into the chimney "to carry off ... any steam or vapor from the cooking in progress below, and serve to ventilate the room or apartment if too warm," providing greater comfort and convenience for the staff at the tolerable cost of wasting heat and fuel.

Moses Pond, Boston, MA. Cooking Range, Pat. 2,990, 1843.

Moses Pond was a long-established Boston stove merchant who, like the Stimpsons, with whom he had cooperated, had depended since the 1820s on David Cooper Wood's New Jersey furnace for his stove castings and, also like them, was branching out in the early 1840s into supplying the growing demand from wealthy city households for a new kind of cooking appliance. Like Beebe's, his was a huge, heavy, grand, and imposing installation, internally even more complicated because it was intended, like the Stimpsons', to serve as an air-heating furnace as well as for all of a large household's cooking.

Ambrose W. Thompson, Philadelphia, PA. Kitchen Range, Pat. 3,501, 1844.

Nothing very distinctive about this -- it's included mostly because of the nice clear drawing of a very derivative brick-set kitchener. Thompson's supposed improvement was the addition of yet another an air-warming chamber allowing the range to use heat which would otherwise have been wasted to warm upstairs rooms. As we can see from the many above examples, this was hardly original. Thompson was just an ordinary plagiarist -- his kitchener's sliding and fold-down oven and firebox doors seem to have been inspired by some of his competitors' established practice, notably the Barrows range, probably the most available in the city's market. By profession he was, and remained, a stationer; I have not seen his range advertised, even in his home city, where the only dedicated range manufacturer at the time was

Julius Fink, Philadelphia, PA. Kitchen Range, Pat. 3,533, 1844.

Julius Fink was a furnace (1841-) and cooking range (1844-) manufacturer with premises on Chestnut Street. Unlike Thompson, Fink achieved originality in his design, and went on to win a First Premium from the Franklin Institute for it. The following year he added "pipes for the circulation of hot water," a "commendable improvement." [Franklin Institute 1845, p. 407]. He advertised it to consumers as the "Celebrated Premium Cooking Range," and alerted them to the fact that "every other similar production, sold as the Premium Range, is an imposition, as this proprietor has no agency or connection elsewhere" -- something which guaranteed only a limited, local market for his design, however good it was, and unlike other inventors including Pierce and Barrows, who already did have sales agents in the city by 1840, well before Fink got started. [McElroy's Philadelphia Directory, 1844, p. 16.]

Fink claimed greater fuel economy for his triangular firebox, increased oven size, and more working space and boiler holes on the top of his stove. The ability to enclose the stove top with sliding doors can only have been for limiting the emission of cooking smells into the house, something of an obsession at the time. Fink remained in business through the rest of the decade, and was still the only recorded cooking range manufacturer in Philadelphia as late as 1850.

Herbert H. Stimpson, Boston, MA. Cooking Range, Pat. 3,587, 1844, reissued as Reissued Patent No. 84, 1846.

Stimpson's new range did not look much different from his 1838 model, but he had altered the internal arrangements (the flues and dampers) to heat the oven. The aim, and claimed achievement, was "to equally, or thoroughly distribute the heat over the exterior of the oven, and permit the operations of baking and boiling, to be carried on" at the same time, without interfering with one another.

The 1846 reissue includes modifications of the above -- a way of strengthening patent claims by amendments to clarify and limit them. Stimpson, or his patent agents, spelt out that his was a three-flue system -- one for each "boiling chamber" either side of the central fire, and the main flue from the fire itself -- "whereby the heat can can be regulated on any part of the oven, the temperature of one part increased or decreased at pleasure by means of the dampers without producing a corresponding change in the other parts." In earlier ranges, he explained, "the oven is heated by the single main flue, ... or by the two ... boiler flues," so that, for example, if you needed more heat for cooking on the stove top there was less for the oven, and vice versa, "and therefore baking cannot be carried out with the same nicety as in mine, where any of the three flues may be wholly or partly closed and thus heat regulated at pleasure."

Moses Pond, Boston, MA. Cooking Range, Pat. 4,064, 1845.

It is difficult to be very sure about what exactly Pond was claiming to be new about this design, because he spent more time saying what he didn't claim, to save himself from legal challenges that this represented no advance on his own Pat. 2990 two years earlier, or Stimpson's Pat. 3589. It was another three-boiler, three-flue range with its oven above and behind the top plate. Pond's was still an air-warming stove as well as an improved range. Like Stimpson, and indeed like almost any other stove designer of the time, he asserted that his particular arrangement of flues and dampers led to superior cooking quality -- "baking evenly and without burning the articles in the oven."

|

| 1845 Moses Pond Billhead (detail), Historic New England Ephemera Collection. |

Jordan L. Mott, New York City. Cooking Range, Pat. 4,248, 1845.

Jordan Mott, New York City's leading stove designer and builder since the early 1830s, produced a range that seemed to combine some features of Fink's (two large, low-level ovens and two distinct working spaces either side of the fire) and some from Barrows's (the drop-down doors) with the rotary top from his and others' cooking stoves at the time, which enabled the cook to bring any one of the four cooking holes near to hand for working, and directly over, or further from, the fire, to control cooking heat. (For more about rotaries, see this post.) There was a single big cooking hole over the left-hand oven, for a very large boiler (most likely for domestic water heating). There was also a space behind the fire "for water back for heating water for bathing and other purposes." In addition, the range had Mott's patented fuel-feed door above the fire, for ease and safety in refuelling.

Mott explained that his stove-derived layout, with each oven wrapped in damper-controlled flues, and the rotary top, allowed for larger ovens in a more compact, convenient, and user-friendly appliance: "As ranges are usually set within the fire-place, there is no way of removing the boilers from the top except over the front, which has been very inconvenient and by some persons almost impracticable with those heretofore in use, particularly when boilers are set in the rear, or when the breast of the chimney is low."

Mott's experienced attention to practical details of manufacture and use showed throughout his comparatively short, concise description. "The sides and back of the fire-chambers against which the linings rest, are so made that a section of each can readily be removed when defective by burning out and its place supplied at a small expense. In the top plate of the ovens I usually make depressions from one half to one inch in depth to receive sand, ashes or other bad conductors of heat, which serve to equalize the heat in the oven by preventing the top baking faster than the bottom."

Mott's was not what would later be termed a fully "portable" range, but it pointed the way. It was the product of a stove maker rather than of a specialist range-builder. Unlike those of most of his competitors, Mott's range was factory-built and (probably) partially assembled, then shipped and installed as a unit. It was not customized and then built in situ. It dispensed with the inconvenient oven behind and above the stove, and it was built with the user in mind.

Herbert H. Stimpson, Boston, MA. Cooking Range Back, Pat. 4,516,1846.

Designed to address a basic problem in ranges like his, with an air-heating chamber behind the fireplace: cracking of the iron plates between them in repeated cycles of heating and cooling, admitting "gas that vitiates the heated air, and renders it unwholesome."

|

| 1846 Stimpson Range Ad., Boston Courier clipping, Historic New England Ephemera Collection. Spells out its difference from, and superiority over, Moses Pond's "and all other Ranges." Note the hot-water cylinder and tap built into the brickwork to the left of the range. |

Julius Fink, Philadelphia, PA. Cooking Range, Pat. 4,550, 1846.

A modification and simplification of his earlier design -- just four boiler-holes, and no sliding screens to shut off the cooking top (perhaps American households were getting used to cooking smells, or simply appreciated that shutting off the range's working surface was an inconvenience not worth having?). It demonstrates his response to his ranges' performance in practice, and his customers' needs: "It is a point of much importance to construct a range in such manner as that it may readily be removed from one fire-place to another with little or no disturbance of the brick work, or occasion for expensive setting." Portability would suit range users who rented their houses rather than owning them, and might expect as frequently as every year, or even owner-occupiers who did not wish to leave an expensive fixed investment behind when they left. He achieved this objective by redesigning the range and also by building more of it from large cast-iron plates rather than, presumably, sheet-iron riveted together. The range had space for a water-back, and also for the warm-air heating facility that residents of multi-storey city houses seemed to appreciate.

George E. Waring & Alexander S. Wolcott, Stamford, CT. Cook Stove / Kitchen-Range, Pat. 4,599, 1846.

Described as a "Cook Stove" on the drawing and a "Kitchen-Range" in the description, perhaps because, like Mott's, it was really a hybrid of the two, a free-standing foundry-manufactured cook stove with a broad front, made to be installed into a quite small, flaring fireplace opening but not built-in. There were the usual claims about the uniqueness of its flues, to provide enough patentable matter. Waring spelled out that though what they patented was a single-oven design, they contemplated making a larger, more range-like version with an oven either side of the fire. Note the top of the range, with five cooking holes, four of them with removable centre-pieces ):( in the style of up-to-date, high-end cook stoves. These allowed large griddles or oval boilers to be used, as well as round utensils. This feature had also showed up in Beebe's great set range of 1842. Waring and Wolcott, like Mott and Fink, were designing and making ranges more suited to American middle-class urban households who were, by the mid-1840s, used to stove cooking and its conveniences, but needed (and could afford) the greater capacity only provided by the range.

John P. Hayes, Boston, MA. Cooking Range, Pat. 4,720, 1846.

Hayes was a Boston coppersmith. His patent drawings make his range look like just another large, heavy, expensive, complicated, built-in set range for wealthy urban households. His principal claim on its behalf was quite a common one among stove inventors, better baking -- in his case to be achieved by pre-heating air to ventilate the oven and assist the cooking. Many Americans, used to properly roast meat (i.e. cooked by radiant heat in front of a fire) were prejudiced against the taste and wholesomeness of meat baked in a closed iron oven. Hayes, like other inventors dealing with this source of inexperienced consumers' resistance to stoves, claimed that his arrangement enabled them to "bake to a much better advantage" and rendered "meats or other articles ... much more palatable than when cooked in the confined air of a close oven, as is the general custom." His range's air-heating passages could also be used to warm air for space heating purposes.

|

| Adams's Boston Directory, 1847-1848, p. 321. |

From a contemporary advertisement we can see that Hayes's range was actually turned into a marketable product, perhaps by its manufacturer and seller, a local stove firm that must have bought his patent rights. The way this was done was by turning it into a free-standing appliance, so that "It can be set in any ordinary fireplace, with as little trouble as a common cookstove. By purchasing this Range, you get a better article, and save from $8 to $10 mason work. [$5,610 - $6,730 at 2016 relative values] It is as easily removed and set up again as any common stove." A.A. Lincoln, the stove's maker and vendor, clearly understood how the market for ranges could be grown: by making them cheaper, more convenient, and more like the stoves that consumers were already familiar with. As we have seen already, in the mid-1840s other inventors and manufacturers with their roots in the stove trade were reaching the same, to be honest pretty obvious, conclusion.

Moses Pond, Boston, MA. Cooking Range, Pat. 4,830, 1846.

Another large, brick-set range, but with six boiler holes rather than the usual three, because it was "very desirable to increase the capacity of a range by the addition of other boilers." As we have seen, many other designers had already managed to include more than three boiler holes, whether in brick-set ranges like Pierce's, or more stove-like arrangements such as Mott's and Waring & Wolcott's. What Pond meant was probably that competitors and innovations such as these had shown up the limitations of ranges like his earlier models, Barrows's, and Stimpson's, and helped drive imitative improvement. Mott claimed that his redesign enabled him "greatly to increase the capacity of my cooking range, and to regulate the boiling more efficiently than by any other means known to me."

Samuel Pierce, Troy, NY. Hot Air Cooking Range, Pat. 5,248, 1847.

Similar to Waring & Wolcott's in shape, and to Mott's, Fink's, and Hayes's in character, i.e. an all-cast unit, made to be installed into a cooking fireplace rather than built in, but (unlike Waring & Wolcott's) too large and heavy to sit on its own legs, so squatting directly on the kitchen floor. Pierce was by this time a stove rather than a range maker, and was based in Troy, the centre of stove innovation. His range had a closed firebox like a stove rather than the open fire still common among range builders. It also incorporated a stove innovation -- heating air to circulate through the oven (see the Hayes range, above) in chambers around the firebox, and then discharging the spent air into the ash pit, to increase the efficiency of combustion. His brother George advertised in 1848 that "recent improvements" made their ranges "decidedly more convenient and economical than any in the market."

John M. Dearborn, Boston, MA. Cooking Range, Pat. 6,198, 1849.

Dearborn was not a novice inventor -- his first patent, 2785X, had been for a pump, in 1817. He started in business as a machinist and machinery seller in the 1820s and 1830s, but by 1840 he had moved into the growing stove trade, running a "stove factory" as well as serving as a sealer of weights and measures. Between the 1847 and 1848 issues of the city directory he changed the way he described himself: now his business was Ranges, as it would remain until his retirement in the late 1860s.

Dearborn's range, like Hayes's, was a free-standing appliance, probably made to sit on round ball feet rather than a stove's standard cabriolet legs because they suited its weight better. It was stove-like in other respects too, e.g. the rotary vents in the front of the boiler chamber, firebox, and oven (A); the small auxiliary ovens beneath the boiler chamber (left) and the main oven (right), "very useful for simply warming pies bread or other matters when the main oven may be in use," and occupying space usually wasted, "in all ranges I have heretofore seen, filled with brick"; and the fact that the firebox could be closed with an iron door "when necessary, or when it may be desirable to burn the fuel by the process of slow combustion, adopted in what is usually termed the air-tight stoves."

Dearborn's customers could have the best of both worlds -- they could roast meat in a tin kitchen in front of the fire, or they could close it up, use less fuel, and be less likely to be burnt when working at the stove. They could also burn long wood as well as coal, another way in which he increased his pool of potential customers to include rural and small-town households in communities where wood was still the principal fuel. Fuel-saving was one of Dearborn's main claims: his range was "admirably adapted for the economical use of fuel, perhaps more than any other one heretofore made."

|

| 1848 Boston City Directory, advertising section, p. 15. |

As with Hayes's range, an advertisement allows us to visualize and understand the real thing consumers bought and used even better than the detailed patent drawings. Note (a) the fact that the range was available in different sizes, the six boiler hole type suitable for ordinary prosperous households (at a time when stoves only had four), the fourteen-hole probably designed for hotels, restaurants, and institutional kitchens; (b) the emphasis on the obvious convenience of having an oven at the front of the range rather than raised above and behind it, as in most set ranges. Dearborn's range is shown installed into an old cooking fireplace alcove, like a set range, but it could also be free-standing; it was thus, as advertised, both "portable and stationary."

Frederick S. Merritt, New York City. Cooking Range, Pat. 6,264, 1849.

Merritt was a Manhattan tinsmith between 1845 and 1850, when he moved his business to the city's stove district and changed its description to stove manufacture and, by 1852, stove and range warehouse. His range was "constructed, as ranges commonly are at the present day, of iron castings or plates." It was 3'9" wide, a mere 1'8" high, and 1'10" deep, with two ovens either side of a central fire chamber, and six cooking holes, i.e. small but entirely conventional. Its claimed uniqueness, and advantages, resided, as with other inventors', in its internal arrangements, giving it both fuel economy and cooking quality: it was an "unequaled" baker, with flues on all sides of the ovens "in such a manner that the baking is done in a most satisfactory and expeditious manner.... by opening and closing the dampers, the draft may be turned, and the heat concentrated upon almost any point at pleasure." He called it "The Ladies' Friend."

|

| From E. Porter Belden, New-York, Past, Present, and Future (1850), p. 121. |

Philip Rollhaus, Port Chester, NY. Cooking Range, Pat. 6,715, 1849.

Rollhaus first showed up in the city directory in 1845, in partnership with William P. Abendroth, living and running a stove foundry at Port Chester, 30 miles north-east on Long Island Sound, and selling stoves from a Water Street warehouse. They also manufactured and sold the "newly improved" Barrows Range, "decidedly the best in the United States. It is the most economical in fuel and by it a far greater amount of cooking can be done than by any other." By 1847 he was in business on his own account, and began to specialize in ranges, a trade he remained in for the following decade.

| |

|

Rollhaus's range was like Merritt's, conventional in appearance and arrangement but distinguished from others by the flues around its ovens. Rollhaus's were adapted from stove practice -- "diving flues," i.e. the hot air was made to circulate from above the top plate of the oven, down the sides and up the back, "causing the bread or other articles being baked to be heated on all sides alike." The patent record is incomplete -- it lacks the main illustration -- but an 1850 advertisement shows a large model of his "Knickerbocker" range installed, with eight cooking holes and a hot-water cylinder.

Nicholas Mason, Roxbury, MA. Cooking Range, Pat. 6,923, 1849.

Mason's range was, he claimed, "compact and convenient ... capable of supplying all the wants pertaining to the culinary department, as well as to form a heater to warm the rooms of the house in which it is situated, with a slight amount of fuel considering the benefits accomplished." It had one oven to the left of the fire, one above and behind it, and a water boiler to the right. It made the usual claims about the uniqueness of its internal arrangements, but was just another variant on the built-in brick-set range.

James MacGregor, Jr., New York City. Cooking Range & Air-Heating Furnace Connected Therewith, Pat. 7,142, 1850.

Another large (eight-hole) built-in combination cooking and heating range, with three special features: "a constant circulation of hot air" in the ovens, for the same reasons as in Hayes's 1846 patent 4720; detachable pieces in the top plate allowing boiler holes to be combined with one another into extra-large holes, a development of a standard stove-top feature already seen in Mott's in 1845, No. 4248, and Waring & Wolcott's in 1846,No. 4599; and springs on the hinges of Barrows-pattern drop-down doors, to prevent them from fracturing either themselves or the range front if they crashed down by accident.

MacGregor was an upstate New Yorker with two patents to his name already -- for a Heating Stove, No. 4350, 1846, and a Cooking Stove, No. 5296, 1847. His first range patent was accompanied by two others for an Air-Heating Furnace, No. 7143, and a Double-Oven Cooking Stove, No. 7193, in the same year, and then a Cooking Stove and Range, No. 11673, in 1854 (see below). MacGregor established himself as a Manhattan "Patentee, manufacturer and dealer in heating furnaces, hot air cooking ranges, register frames, steam boilers, coffee and tea pots, corn and bark mills, &c, wholesale and retail" (1856 Directory) on the strength of these and other useful innovations.

Herbert H. Stimpson, Boston, MA. Cooking Range, Pat. 7,151, 1850.

Stimpson was attempting to compete with some of the New York-style set ranges illustrated above, with their low-down ovens and growing numbers of boiler holes, by improving his old-style range with its oven behind and above the fire, and just three big cooking holes. He called this the "Double Range," though he could still only manage to squeeze in four holes. He admitted that in ranges made like his older ones "the products of combustion in passing from the fire chamber to the flues around the oven, can only strike against a small part of each of the two back boilers." A new arrangement of flues and dampers was supposed to get around this drawback. Whether it worked well enough to sustain his range layout as a competitor for more sophisticated New York ranges is another question. Probably the most interesting feature of this patent is the clarity of the drawings, showing the internal arrangement of this style of direct-draft range.

Elias T. Beers, Honesdale. PA. Cooking Range & Heating Air, Pat. 7,231, 1850.

Another of the many early ranges aiming to do everything -- cook, heat water, and warm air -- with a single substantial, built-in piece of equipment. Nothing particularly interesting about it, and, as it was very clearly built in situ rather than manufactured and/or assembled, even if Beers succeeded in selling any, his market cannot have been large.

Herbert H. & Frederick H. Stimpson, Boston, MA. Water-Back for Cooking Ranges, Pat. 7,401, 1850.

Another practical improvement from two of the most experienced range-designers in the country, intended to improve the functioning of water-backs by making them easier to install and repair, and less liable to clog up from the deposition of sediment in the water supplies, private or public, on which they depended.

Moses Pond, Boston, MA. Cooking Range, Pat. 7,946, 1851, reissued as Reissued Pat. 240, 1853.

A new type of built-in range, with the oven still elevated, but offset to the side of the firebox and four-hole stove-top, i.e. the cook would no longer need to stand straight in front of the fire and to reach across the top in order to access the oven. Pond was also responding, like the Stimpsons, to the increasing demand for water-backs as a standard feature, designing his so that it could cope with being installed in a fireplace alcove with pipework on the left or the right.

Pond and the Stimpsons, former collaborators, were by this time deadly (or at least litigious) rivals in their ongoing quest for local market leadership. The judges at the Sixth Exhibition of the Massachusetts Charitable Mechanic Association (New England's equivalent of Philadelphia's Franklin and New York's American Institute annual competitive displays of manufactured goods) in 1850 were unable to reach a conclusion about whose were best, so they fudged it: "were each individual of the board called upon to purchase a Range for his own use, he would select Pond's or Stimpson's newest pattern... We are aware that, in regard to the priority of invention, in some parts of their respective Ranges, there is an open question between the proprietors of Stimpson's and of Pond's; but, inasmuch as our opinion upon that question, would be conclusive as against neither party, we deem it neither in our power nor within our province to enter upon it." [p.79]

|