Note: since writing this, I have uploaded all of the illustrations into a Flickr album, for greater convenience of viewing. The sequence of images relevant to this post begins here. You can have them open in another tab or window and swap easily from reading the blog to looking at zoomable versions of the drawings. I have also, as in Part 4, begun to set out patent titles with more descriptive detail than in the official version, which sometimes says nothing more than "Stove." Added detail -- stove type or even name -- is within square brackets.

1843: 1 Improvement, 2 Designs

No. 3330Thomas, John E.

Albany

Cooking Stove

November 6, 1843

Witnesses: Topper, Calvin & Hamilton, W.A.

This seems to have been the usual sort of compliment stove inventors paid to an unusually successful stove, i.e. rampant copying, in this case apparently of P.P. Stewart's stove. Thomas called his the "Non-Radiating Summer and Winter Air-tight Cooking Stove," wrapping his oven and firebox in "a diving flue on each side and combining therewith non-radiating substance on the outside, around the oven; part of the flue being ribbed to extend its radiating surface." "[T]he sides are ribbed so as to look like a row of columns." The base plate of the stove was lined with Plaster of Paris, a nonconducting material; the sides had "a movable covering of the same material, that can be taken off," like Stewart's, except that his were made of polished tin.

D5

Ripley, Ezra

Troy

Stove-Column

August 12, 1843

Witnesses: Geer, Erastus & Hadley, A.K.

JOHNSON [Elias], GEER [Gilbert], & COX [David B.]

This was the very first use of the new Design Patent system by a stove designer. It was for Ripley's intricately decorated and expertly made columnar flue for a heating stove, made to look like a rather mythical dolphin (it had scales), and cast in one piece, possibly using Ripley's own earlier invention patent for this process.

For Ezra Ripley's many patents, see the blog post about him and his partner Nicholas Swart Vedder, Troy's most active and influential stove designers for most of the next four decades. It would take too much space to copy the entries for Ripley's many patents here. But at least including them here alongside those of his neighbors, clients, and rivals enables us to see how large his contribution was. I'd suggest that you should open that post in a separate tab or window, so that you can flip from one to the other if you wish to compare and integrate Ripley's work with that of his neighbors. Or look for them in the Flickr album, starting here.

Blanchard, Alonzo L.

Albany

Heating Stove

26 August 1843

Witnesses: Greenough, J.J. & Goddard, P.M. [?]

The illustration is a poor, small, dark image of Blanchard's statue of George Washington on a plinth. It was "for ornamental purposes such as Radiators for Stoves &c." of the sort Blanchard had recently patented. The description of the statue is detailed and precise.

Witnesses: Elliott, William P. & Johnson, Albert E.

A stove with a peculiar form -- long and narrow. Pettes made the usual sort of claims inventors made on behalf of their cook stoves -- fuel economy and a large, controllable oven. Probably a "paper patent" like John Thomas's, for a stove destined not to be made, sold, used, or even to have its useful features incorporated by other stove makers.

No. 3628

Hermance, John C.

Schenectady

Cooking Stove

June 13, 1844

Witnesses: Jones, Thomas P. & Bishop, William

Unlike Thomas's and Pettes's, Hermance's stove was a merchantable product -- a rival of Buck's, Stewart's, and other large-oven stoves. Its patent was a full, detailed, very professional piece of work -- understandable as Hermance's agent was Thomas P. Jones himself, former editor of the Journal of the Franklin Institute and director of the U.S. Patent Office. There is even enough detail in the drawings to enable one to understand how its constituent plates fitted together.

Hermance's stove had two ovens A and B rather than a single large one, and also a detachable roasting or baking reflector oven sitting on the hearth. It had four boiler holes, with the covers made as concentric cast rings so that they could easily be adapted to utensils of different diameters. The center plate between the two front boiler holes was also removable, so that with all three taken out there would be room for a griddle straight over the fire. These were not new features, but Hermance was building other makers' good ideas into his stove to suit growing customer expectations. His explanatory text sounds like the work of an ingenious, practical manufacturer, learning from experience -- e.g. "To prevent the warping or cracking of the oven-plates and of the boiler-hole covers, I form angular grooves in them, making the depression on one side equal to the projection on the other. These grooves and projections ... have been found effectual in producing the desired end."

Wager, James

Troy

Cooking Stove

July 9, 1844

Witnesses: Jones, Thomas F. & [?]

Chollar, John B. & Parmelee, Homer

Troy, West

Railway Stove

July 11, 1844

Witnesses: Hart, Jonathan & Marshall, I.H.

Witnesses: Elliott, William P. & Johnson, A.E.

Firebox in the middle of the stove, immensely complex double flue system -- "by which arrangement the heat is made to circulate twice around the oven instead of once, thereby causing cooking operation of the oven to be performed with much less fuel than heretofore consumed and more equably." The illustration is only worth including as an example of the sort of scheme people who knew nothing about stoves and stove making sometimes came up with and thought worth the investment of a patent.

No. 3830

Lyon, James H.

Schenectady

Cooking Stove

November 18, 1844

Witnesses: Sinn, A. & Fuller, James

Delivering "more perfect control over the heat applied to the oven during the process of baking" by having a movable firebox. "The invention & improvement herein contemplated" -- not practical. Another mere paper patent.

No. 3861

Potter, William L.

Clifton Park

Cooking Stove

December 19, 1844

Witnesses: Maher, Edward & Hemingway, Daniel

A square stove with a small upper oven behind the firebox and a larger lower oven the whole depth of the stove, plus a complicated and unconventional flue system taking up a lot of room within the stove body. Sounds like a real stove, i.e. it probably was made, at least in prototype form, but not one which made any impact on subsequent stove design. A dead-end.

D22

Whitney, Amaziah

Albany

[Step] Stove [with Elevated Oven]

July 19, 1844

Witnesses: Ellison, Andrew Jr. & Outivin [?], John

The oven runs from front to back, as in the original Granger patent.

D25

Ripley, Ezra

Troy

[Parlor] Stove-Plate

November 26, 1844

Witnesses: Cox, Abram & Gale, Ansel H.

Assigned to JOHNSON, GEER, & COX [Troy]

A parlor stove. Very floral [including "a bunch of melons & grapes"] -- "to be used in the manufacture of air tight or other box stoves." "It is impossible to describe accurately in language the ornamental carvings on the surface of the plates but the same is represented as accurately as possible in the side plate of the Engraving or drawing hereto annexed and by the pattern or model herewith transmitted."

1845: 11 Improvements, 7 Designs

Stanley, Henry

Poultney, VT

Coal Stove

January 4, 1845

Witnesses: Jones, Thomas P. & Brundage, Edwin L.

Henry Stanley's heating stove, columnar in form, was sold as "Stanley's Coal-Burner." Its key distinction was the arrangement of air-warming flues between the firebox and the plates forming its decorative shell, to maximize its efficiency without any plates being overheated, distorted, and/or discoloured. Though he was still living and working in Poultney (65 miles NNE from Troy), I'm including this here because Stanley soon moved to Troy, and his stove's subsequent patent history was registered there by Charles Eddy and Jacob Shavor, stove makers of Troy, to whom it had been assigned by Stanley's son John. The patent's validity was extended for seven years before it expired in 1859, then reissued several times: RE 944, 10 Apr. 1860, witnessed by A.C. Corse and Thomas Woolcocks; RE 958, 8 May 1860, witnessed by Marcus P. Norton and Henry Stanley himself [by then resident in Albany]; and RE 1,078 on 13 November 1860, witnessed by Norton and Corse. Complex questions about who actually owned this patent and whether Eddy and Shavor's use of it violated the other owner's rights was fought out repeatedly in the courts until 1874, as discussed in this blog post: "Henry's Stanley's Rotary Stove and U.S. Patent Law," which contains illustrations.

No. 3910

Davy, John T.

Troy

Domestic Oven / [Summer] Baker

Witnesses: Thompson, A.A. & Wells, I.F

"A new and useful Improvement in Summer-Bakers." This was a small sheet-iron stove designed to satisfy a clearly felt need of consumers -- an appliance they could use in the summer without overheating their kitchen. Other designers reached the same objective in different ways -- insulating the stove, or adding a "summer attachment" with its own smaller firebox, but venting through the same chimney, which was Davy's own later method.

No. 3939

Davy, John T.

Troy

Cooking Stove

March 12, 1845

Witnesses: Francis, Joseph & Greenough, J.J.

A 4-boiler square cook, with two more boiler holes or a gridiron broiler in the front hearth, which also had its own "fire chamber," i.e. this was what other inventors called a "Summer Attachment." There was an L-shaped oven extending under the firebox, as in the Buck stove, with downdraft flues, but Davy avoided the Buck patent by using a variation of the "sheet flue" form first used by Charles Postley in 1815 (2297X) and then revived by P.P. Stewart. Davy seemed to be inspired by, and competing with, Stewart rather than Buck. His flue promised a "brisk draft ... forming the stove so as to produce the greatest economy of space and use of fuel" and "an equal dispersion of heat all around the oven." "The front of the stove, above the hearth..., is corrugated ... for the purpose of radiating heat in roasting before it..." The patent included six clear drawings, with plans and sections, perhaps showing the influence of Greenough, a professional draftsman and patent agent. Davy was a stove maker from 1840 to 1861, mostly as a partner in the Washington Foundry.

Atwood, Anson

Troy

Air-Tight [Box] Stove

March 26, 1845

Witnesses: Greenough, J.J. & Donn, T.C.

A box stove with corrugated sides. Atwood's claim was to have solved problems that many designers were working on at the time -- making stoves air-tight, so that they would burn more efficiently and controllably. "[T]he manner of constructing the joints at the corners of my stove, and in forming an air chamber in the stove that communicates with the external air below, and discharges into the stove pipe thus supplying a current of air through the chimney when the stove is closed air tight, and preventing the condensing of the smoke, gas, &c." thereby prevented the destruction of the pipe and chimney.

Atwood's design was actually made and sold, though his system for guaranteeing a stove's air-tightness was not widely adopted -- other, simpler ways were found instead. His 1846 sales brochure shows this stove dressed in Gothic style rather than the functional corrugated cast iron of the patent drawing. It was, he said, "not only beautiful in the extreme, but the most perfect example of the kind ever offered in market."

Johnson, Elias & Cox, David B.

Troy

[Cook] Stove

July 22, 1845 [Reissue 138, 19 June 1849]

Witnesses: Sheldon, C.D. & Geer, Erastus [Reissue witnesses: Samuel Pierce & James Shields]

A cooking stove with two fireboxes "distributing the heat over the surface of the oven in the most advantageous manner.... It is found in ordinary stoves that the ovens bake unequal those parts nearest the doors being less heated than the center and in stoves where two fires are used the draft has been unequal or the heat from one or other of the fires has been lost to the oven; by our arrangement both of these evils are avoided."

No. 4159

Low, Francis S. & Leake, John S.

Albany

Cooking Stove

August 20, 1845

Witnesses: Ellison, William S. & Thayer, Benjamin H.

A standard square, flat (i.e. not large-oven) four-boiler stove. All of the claimed difference was in the flues, as usual. Low and Leake were in partnership running a stove business in 1845-1848, Low having entered the trade in 1830 and running a foundry for seven years, while Leake was a former clerk with the New York State Bank. William Ellison was a civil engineer (and patent agent).

No. 4197

Clute, Peter J.

Schenectady

Cooking Stove

September 19, 1845

Witnesses: Rowe, Peter & Fonda, D. Edgar

Clute was a Schenectady foundryman and stove maker. This patent had "a series of dumb flues [including in the doors] ... for the purpose of heating the oven more regularly throughout its sides and ends and effectually." It does not seem to have influenced future stove design in any way, so can be classed with other apparent bright ideas that turned out to be dead ends.

No. 4260

Chollar, John B., Jones, Ebenezer, and Low, Peter

Troy

[Improved Empire] Cooking Stove

Witnesses: Sanders, A.K. & Greene, C.O.

A four-boiler square stove called the "IMPROVED EMPIRE." Its distinctive features were the construction details of the hearth plate and the oven and stove bottom forming flues "with cemented air-tight joints" between three plates "less liable to break than when the bottom is made in one piece." Note the way in which almost the entire top of the stove could be opened up -- both pairs of boiler holes could be turned into a large oval by removing the loose ) ( centre pieces between them, and the I-shaped plate could also be taken out, perhaps for cleaning the flues, perhaps to take a single large cauldron. These were non-patented ways of making the stove more flexible in the ways it could be used.

No. 4284

Robinson, Eli C.

Troy

Cooking Stove

Witnesses: Woodbury, P.T. & Whiting, Daniel

Has a detachable 2-hole "appliance" (or summer arrangement) with its own firebox to go on the front of the stove. Otherwise, just a different flue design.

No. 4299

Pierce, Samuel

Peekskill

Cooking Stove

December 6, 1845

Witnesses: Brundage, Edwin L. & Humphries, Guy C.

A 4-boiler square stove with a distinctive curved plate (not mentioned in the description) at the back of the firebox. "In the ovens of cooking stoves it is a general source of complaint that the heat is too great at the top and too little at the bottom. To obviate the latter of these difficulties I allow the plates on each side of the stove to descend to the depth of 3 or 4 inches below the lower plate ...; and at the lower part of this space I insert a plate ... so as to inclose an air space of 2 or 3 inches between it and the bottom plate ...; the air contained in which constitutes a non conducting medium which prevents the heat from being carried off from the lower oven plate." "To prevent the overheating of the top of the oven and obtain other advantages, I substitute for the ordinary metallic top plate of the oven an open frame of cast iron ... in which I place panels ... of soapstone, or of fire clay. These not only moderate the heat at the top of the oven, but, as less is absorbed by them than by a metallic plate they increase it at the bottom. They have also the beneficial effect upon the articles that are being baked which is produced by the ordinary brick oven, namely that, the aqueous vapor that is disengaged, is absorbed by them and carried off, and the bread or other articles that are cooked do not become sodden as in ovens wholly of iron." There were also draft openings in the firebox doors so that "the air shall be highly heated before it is brought into contact with the fuel, by which means a very considerable saving is effected." The doors were "fitted, as nearly as possible, air tight" and included a sliding latticed register and a corrugated air-heating plate. There was a dividing plate to direct the draft to one pair of holes or the other, but he admitted that "[t]his is not a new feature," i.e. it formed no part of his claim. There was a standard 3-flue design, but note that his bottom flues E did not extend all the way to the front of the stove, thereby evading the Buck patent.

Samuel Pierce, b. 1812, was the son of another Samuel Pierce, the only tinsmith in Greenfield, MA, who introduced cooking stoves to their rural community at the head of navigation on the Connecticut River, and brother of John J., proprietor of the town's Franklin Furnace, who took out a patent on an “Open Cooking Stove” (probably a modified Franklin) as early as 1822 (the lost Patent 3473X). In 1833 he moved to New York City and opened a stove store on Lower Broadway. By 1835 he was already describing himself as a patent range manufacturer, a description he shared with none of his competitors, and in 1838 he did indeed patent a prizewinning brick-set, anthracite-fuelled cooking range which other New York firms made for him, and also sold manufacturing rights outside the city. In 1843 he decided to devote himself to stove invention full time, leaving the New York City business in the care of an older brother who would continue to sell what he invented, and moved to Peekskill, where there were foundries and pattern-makers to work with and “a pleasant place of residence of my family”. In 1845 he moved to Troy, just eighty miles west of Greenfield, where he still had a farm, and stayed there for the next couple of decades, producing twenty-four original patents for heating and cooking stoves and ranges in a thirty-three year inventing career.

Pierce's was one of the most consequential, long-lived, and profitable of stove patents. It was reissued first in April 1847, by which time he had moved to Troy, as Cooking Stove [Reissue 91], witnessed by J.J. Greenough and J.W. Thayer. The patent was assigned to Johnson & Cox outright for a capital sum, and Pierce also became their superintendent of stove manufacturing, a salaried position, as well as a loyal defender of the patent in which they were all interested. By this time the stove embodying his innovations, the "American Air-Tight," had become one of their most important, market-leading products, a "most remarkable stove" enjoying "an unparalleled success," one marked also by "the great number of infringements ... made upon each part."

One of the most serious objections to baking in cooking-stoves arises from confining the vapor or gases evolved from the articles under treatment in the oven, which, from the closed nature of the ovens and the material (iron) of which they are composed, do not permit their escape, and thus impart a disagreeable flavor to articles baked therein. To avoid this serious objection numerous devices have been invented to permit the escape of the noxious gases, which devices not only add to the cost and complexity of the stove, but at the same time waste much of the heat. Another objection arises from the difficulty of heating the different parts of the oven equally... but all these plans [defenses against uneven baking -- "flues & interposed air-chambers"] are more or less complex and liable to derangement, and but partially effect the one purpose of equalizing the heat.

Pierce's lining for the oven top -- now stipulated as firebrick -- and pre-heating air chamber in firebox were the sure remedies for all of these problems.

There was a further reissue in July 1847, Cooking Stove [Reissue 99], witnessed by Charles M. Keller and J.M. Thayer, again assigned to Johnson & Cox; an extension in 1859, to prevent the patent from lapsing; another in December 1861, Cooking Stove [Reissue 1,240], witnessed Frank Scott and Marcus P. Norton, initially assigned to Johnson & Cox and then back Pierce himself, i.e. he repurchased his own intellectual property from them, and finally Reissue 1,241 that same day, with the same witness and assignment details.

Witnesses: Elliot, William P. & Johnson, A.E.H.

Myers's claim was the manner of heating the upper part of oven with air, the design of the flues, and the facility to divide the firebox in two, and run on just half of it -- another way of dealing with the need to be able to do necessary cooking, especially in summer, without wasting fuel and overheating the kitchen. I have never seen this innovation included in stove on the market.

D27

Low, Addison

Albany

[Columnar Parlor] Stove

February 12, 1845

Witnesses: Ott, Oran & Hastings, F.H.

Assigned to LOW, Francis S. & LEAKE, Francis S.

An ornamental, columnar parlor stove whose crowning glory was "an American Eagle, surmounting the shield of the United States." This was a very patriotic stove design, brought onto the market in the middle of the Oregon Crisis and in the run-up to the Mexican War.

|

| All that is missing in the Metropolitan Museum's example of a Low & Leake stove is the decorative piece filling the gap between the columns. |

Low & Leake's partnership only lasted for about three years, 1845-1848, but Low carried on at the Hudson River Foundry (with other partners?) for at least a decade.

D31

Ransom, Samuel H.

Albany

[Step] Stove

July 10, 1845

Witnesses: McElwain, Samuel & Ott, Oran

This was a technically very ordinary four-boiler step stove with an attractive decorative scheme. The doors on the firebox each contained a vase of flowers; the oven doors were "in the style of Louis XIV." Samuel Ransom was the nephew of Joel Rathbone and, with his cousin John F., had taken over the management of his enterprise in 1840 when Joel retired, a very rich man after a working life of just eighteen years. He devoted the rest of his life to gardening, art collecting, travels in Europe, community service, and investing his capital in other local businesses, including his nephews'. Ransom remained in business until 1882, and his company outlived him, under his sons' control. Of his witnesses, Ott was a local Commissioner of Deeds; McElwain was not in the directory, and probably a patent agent.

D32

Ripley, Ezra

Troy

[Parlor] Stove Ornaments

July 14, 1845

Witnesses: Atwood, Anson & Adancourt, F.

Assigned to JAGGER, TREADWELL, & PERRY [Troy]

A square (not columnar) parlor heater, rococo (?) in style.

D33

Atwood, Anson

Troy

[Box] Stove

July 14, 1845

Witnesses: Mann, J.D. & Starbuck, N.

Assigned to STARBUCK, Benjamin

A Gothicized six-plate or box stove. "The surface of the plate between and within said arches D is ornamented with small fanciful carvings as represented in the drawing, and not susceptible of verbal description." They appear to be grape vines. The drawing is dated 13 Sept. 1844. Compare the style of this stove with his Air-Tight, No. 3975 above.

Nathaniel Starbuck ran the Mechanic Street Furnace in Troy, one of the city's oldest, between 1821 and at least 1846, when they ran into financial difficulties. The firm was resurrected as Starbuck Bros. by 1854.

D37

Low, Addison

Albany

[Premium Cook] Stove

October 7, 1845

Witnesses: Low, William H. & Weld, J. Ruggles

Assigned to RATHBONE & Co.

The side plates (with the oven door) and front (with the firebox doors) of a Premium, i.e. four-boiler (step) cook stove with "a double border of leaves, buds &c including a composition of fruits flowers &c as grapes melons, pears, nuts &c" and a flower vase with "bundles of reed inclosed between leaves & tied with crop fillets".

John F. Rathbone's partners at the time in the company his uncle Joel had helped him establish alongside Samuel Ransom's when their partnership ended in 1844 were Benjamin Thomas and Addison Low, with whom he remained in business until 1850. A ledger with their accounts for the partnership's first fourteen months survives, providing a unique insight into the operations of a major Albany foundry quite close (a decade or so) to the local industry's beginnings.

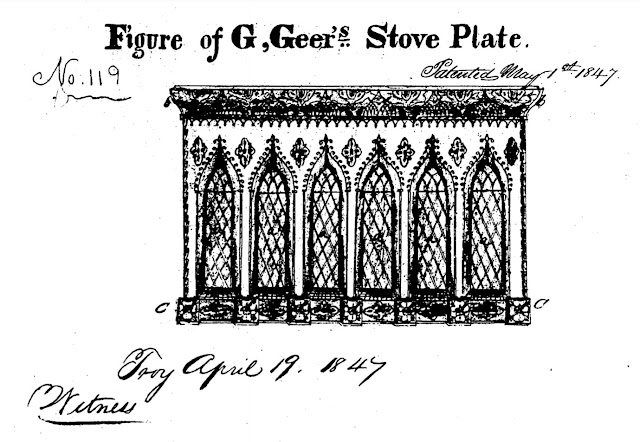

D41

Ripley, Ezra

Troy

[Parlor] Stove Side & Top

October 16, 1845

Witnesses: Sheldon, C.D. & Geer, Erastus

Assigned to JOHNSON, GEER, & COX

Parlor stove. The description uses the standard "impossible to describe" language, but there is no reference to a model, i.e. people are getting used to Design Patent rules, and difference from an Improvement. "The carvings on the surface are designed to represent the front of a Gothic Cottage, with two large Gothic windows ... surrounded by Gothic mouldings interspersed with rosettes & beads..."

Ripley, Ezra

Troy

[Parlor] Stove

November 12, 1845

Witnesses: Adancourt, C.L. & Adancourt, F.

Assigned to LOW, CHOLLER (), & JONES

Parlor heater.

1846: 11 Improvements, 22 Designs

FRONT LOWER PLATE: "a female figure holding a wreath in the left hand and extending the right arm toward the sea. Two vessels are seen upon the water, which is bounded in the background by distant hills. The figure reclines upon rocks & has foliage behind it. The panel is bordered with heavy scroll-work & foliage. The rear is the same, except that the filling of the panel is omitted."

No comments:

Post a Comment

Comments will be moderated to prevent spamming, phishing, and advertising. If you wish to do any of these things, please don't waste your time and mine.